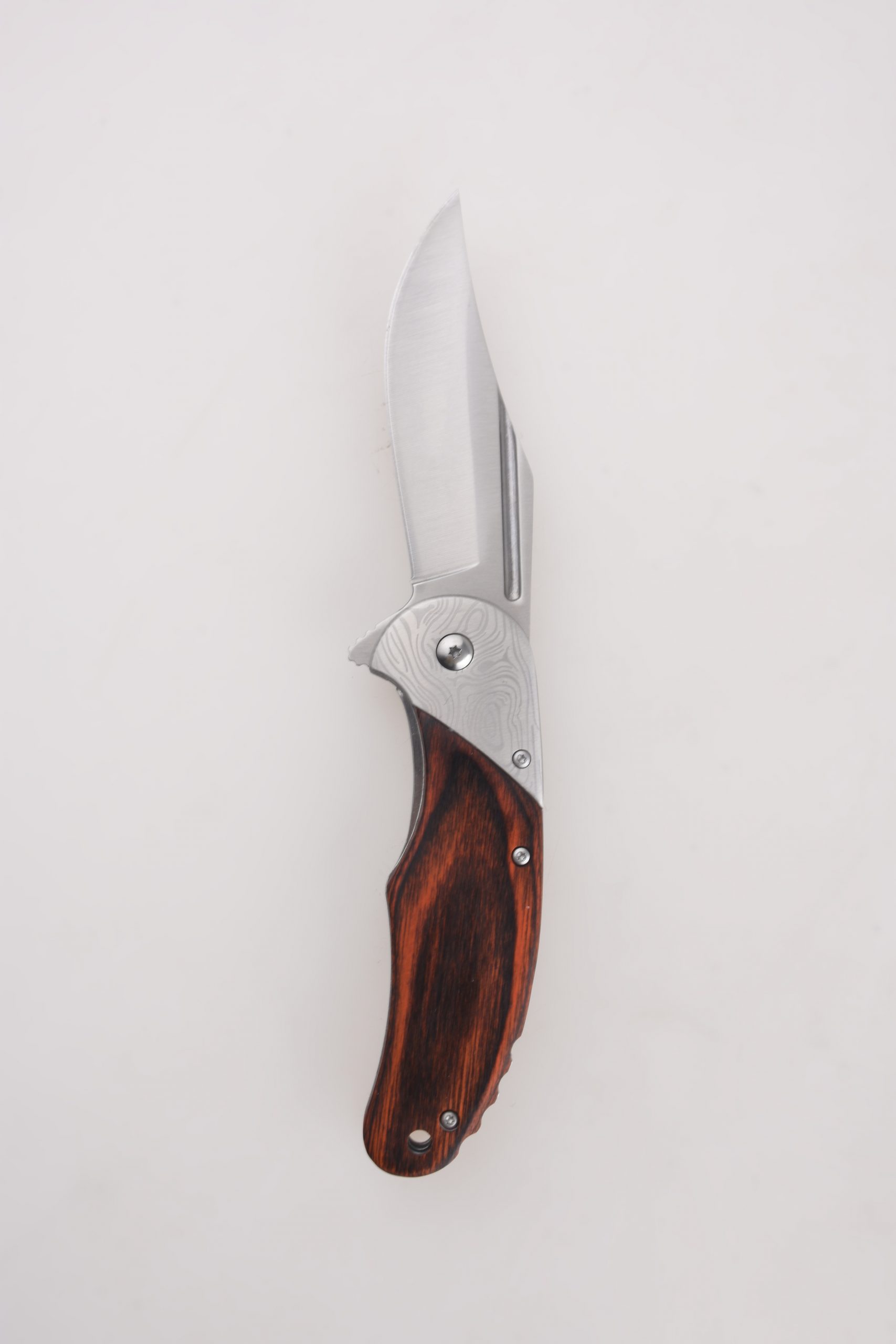

제품 번호.: FR-0509

아이템 세그먼트: 접는 나이프

블레이드 재질: 3Cr13

핸들 재질: 2Cr13 + 컬러 우드

블레이드 HRC: 50-52

블레이드 두께: 0.106” / 2.7mm

블레이드 길이: 3.5” / 89mm

핸들 두께: 0.508” / 12.9mm

총 길이: 8.31” / 211mm

무게: 6.08온스 / 172.5g

블레이드 스타일: 클립 포인트

핸들 색상: 나무

포켓 클립: 팁다운

잠금 장치: 라이너 락

열린 길: 플리퍼

블레이드 마감: 새틴

블레이드 그라인드: 플랫 그라인드

ODM 일반 MOQ: 1200

주목: Pivot에 슬립 조인트를 만들 수 있습니다.

In a realm where precision intertwines with elegance, the Shieldon FR-0509 OEM folding knife emerges as a quintessential tool for enthusiasts and connoisseurs alike. This fine-crafted instrument epitomizes the fusion of functionality and artistry, a token of Shieldon’s unwavering commitment to manufacturing and trading excellence. Let’s unfold the tapestry of attributes that make the FR-0509 not just an item but an experience.

Sculpting the Blade

At the heart of the FR-0509 lies its clip point blade, forged from high-quality 3Cr13 stainless steel. Renowned for its resilience and ease of sharpening, this steel formulation strikes a delicate balance between durability and maintenance, offering a blade hardness of 50-52 HRC. The blade’s thickness of 0.106 inches (2.7mm) provides a robust spine, while the blade length of 3.5 inches (89mm) ensures versatility for a wide range of cutting tasks.

Accentuating the blade’s allure is the blood groove, a feature that not only enhances the knife’s visual appeal but also contributes to reducing the blade’s weight, optimizing its balance. The satin finish on the blade adds a subtle sheen that is both aesthetically pleasing and practical, reducing the appearance of scratches and wear over time. Mastery of the flat grind technique ensures that the FR-0509’s blade is sharp, reliable, and ready for precise slicing.

Crafting the Handle

The handle of the FR-0509 is a testament to Shieldon’s attention to detail, featuring a blend of robust 2Cr13 stainless steel and exquisite color wood. The juxtaposition of materials not only creates a striking visual contrast but also offers a sturdy yet comfortable grip. With a handle thickness of 0.508 inches (12.9mm), this knife promises a substantial feel in the hand without compromising on elegance.

Functional Aesthetics

The clip point style of the blade is a time-honored design that provides a sharp and controllable point, making it ideal for piercing and precision work. The inclusion of a tip-down pocket clip reaffirms the knife’s readiness and accessibility, a nod to practicality for everyday carry enthusiasts.

Innovative Lock Mechanism

Security is never an afterthought with Shieldon. The FR-0509 employs a liner lock mechanism, a reliable and tested system that ensures the blade stays open during use and prevents accidental closure. This safety feature underscores Shieldon’s commitment to user security and trust.

Ease of Deployment

A seamless open way is instrumental for a folding knife. The FR-0509 facilitates a swift and smooth flipper deployment, allowing for quick and easy blade access when time is of the essence. This opening mechanism underscores the knife’s readiness, a feature that users will appreciate for its convenience and efficiency.

Dimensions and Weight

Ergonomically designed, the FR-0509 boasts an overall length of 8.31 inches (211mm) when opened, providing a substantial cutting edge without being cumbersome. The weight is meticulously calibrated at 6.08 oz (172.5g), offering a reassuring heft that signifies quality and durability while maintaining comfortable handling and use.

Customization and Flexibility

Understanding the diverse needs of clients, Shieldon offers the option to make a slip-joint in the pivot, adding an additional layer of customization to meet specific requirements. This flexibility illustrates Shieldon’s capacity to tailor products to the unique preferences of its customers.

Minimum Order Quantity

For Original Design Manufacturing (ODM) clients, the FR-0509 has a regular minimum order quantity (MOQ) of 1200 units. This MOQ facilitates both small-scale operations and larger enterprises to benefit from Shieldon’s manufacturing capabilities, ensuring that quality is scalable to order volume.

결론

The Shieldon FR-0509 OEM folding knife is not just a cutting tool; it’s a synthesis of form and function, designed to satisfy the demanding standards of knife aficionados and everyday users alike. The combination of a blood groove clip point blade, stainless steel and wooden handle, and a reliable lock mechanism make this knife a standout in Shieldon’s expansive catalog.

Shieldon, with its impressive 25-year legacy in the foreign trade industry, has refined the craft of knife-making to an art form, ensuring that each product not only meets but exceeds the expectations of its clientele. Whether for daily use, tactical applications, or as a collector’s piece, the FR-0509 is poised to carve its mark in the hands of those who appreciate quality without compromise.

In choosing the Shieldon FR-0509, you are not just acquiring a knife; you are investing in a piece of Shieldon’s storied tradition, a slice of craftsmanship excellence that carries with it the promise of performance, durability, and uncompromising style.

The folding knife, an essential tool and companion for many, is a marvel of design and function. Whether it’s for everyday carry (EDC), tactical use, or as a collector’s piece, the components of a folding knife are critical to its performance. Two aspects particularly stand out in the production of folding knives – the handle scales and the opening mechanisms. Both elements are pivotal in ensuring the knife is not only aesthetically pleasing but also ergonomic and practical.

Handle Scale Materials in Folding Knife Production

The handle of a folding knife, also known as the scale, is vital for user control and comfort. It is the part you grip and as such, its material can affect the knife’s weight, texture, durability, and price. Here are the most commonly used materials in folding knife handles:

Each material has its own set of characteristics and choosing the right one is a matter of preference, intended use, and budget.

Opening Mechanisms in Folding Knives

The way a 접는 나이프 opens is another crucial component of its design. Different mechanisms cater to various preferences and situations. Here are the most common opening mechanisms found in folding knives:

In conclusion, the materials used for handle scales and the opening mechanisms are key factors in the functionality and appeal of a folding knife. Wood, metal, and synthetic materials offer different experiences in hand, and whether you prefer a manual, assisted, automatic, flipper, or thumb hole opener, the choice will influence how you interact with your knife on a daily basis. Understanding these basics is essential for anyone interested in folding knives, whether you’re a seasoned collector or a newcomer to the craft.

OEM 나이프 프로젝트의 모든 단계에서 도움을 드릴 준비가 되어 있습니다. 귀하의 문의 사항과 예산을 보내주시면 이내 연락드리겠습니다. 24 시간.