제품 번호.: XW-1011

항목 세그먼트: 접는 나이프

블레이드 재질: 3Cr13

핸들 재질: 양극 처리된 알루미늄

블레이드 HRC: 50-52

블레이드 두께: 2.8mm/0.11"

블레이드 길이: 66mm/2.6"

핸들 두께: 12.5mm/0.492"

총 길이: 157mm/6.18"

무게: 70.5g/2.49온스

블레이드 스타일: 낙하 지점

핸들 색상: 실버와 블랙

포켓 클립: 팁업

잠금 장치: 라이너 잠금

방법을 여십시오: 썸 스터드

블레이드 마감: 클래딩

블레이드 그라인드: 평평한

ODM 일반 MOQ: 1200

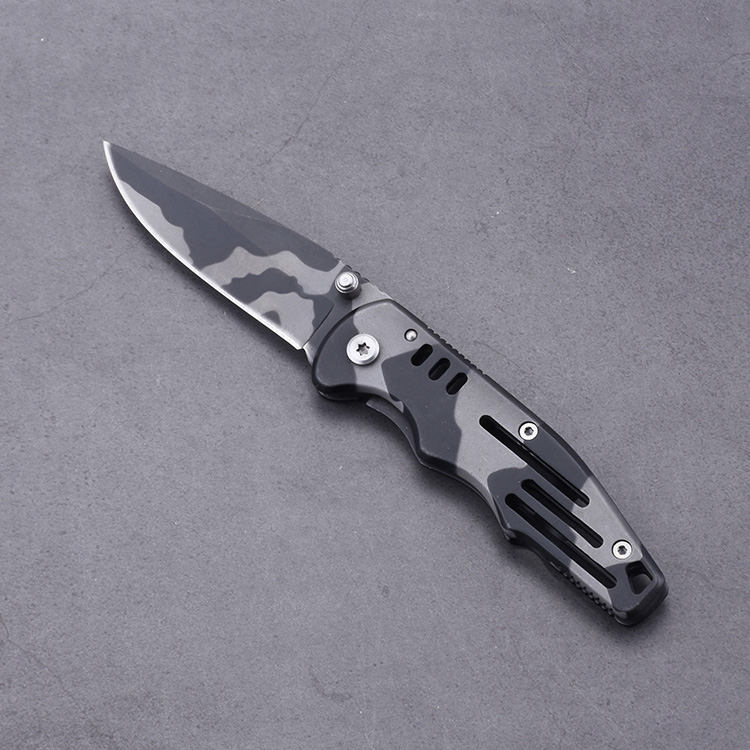

Step into the world of tactical efficiency and sleek design with Shieldon’s latest offering, the OEM XW-1011 Folding Pocket Knife. Engineered for reliability and styled for the modern user, this folding knife combines a robust 3Cr13 blade with a stylish anodized aluminum handle, creating a blend of durability and elegance. Designed for OEM customers, the XW-1011 model is a testament to Shieldon’s commitment to quality and customer satisfaction in the Manufacturing & Trading Combo business.

Product Description:

The Shieldon OEM XW-1011 Folding Pocket Knife is crafted for those who demand precision and strength in a compact package. The folding knife segment welcomes a new contender that does not compromise on quality or design.

Blade Specifications:

At the heart of the XW-1011 lies its formidable blade, constructed from 3Cr13 stainless steel. Known for its impressive resistance to corrosion and wear, 3Cr13 ensures that the blade maintains its integrity in various conditions. With a hardness rating of 50-52 HRC, it strikes an optimal balance between toughness and ease of sharpening.

The drop point style of the blade, with a thickness of 2.8mm (0.11 inches), offers a versatile cutting edge ideal for a range of tasks. Its 66mm (2.6 inches) length provides ample surface for precision slices while remaining compact enough for convenient carry. The flat grind on the blade ensures a sharp edge and easier maintenance, while the cladding blade finish gives it an attractive sheen and enhances its resistance to the elements.

Handle Features:

The anodized aluminum handle of the XW-1011 is a marvel of engineering. With a sleek silver and black color scheme, it’s not only visually striking but also provides an excellent grip, reducing slippage and increasing safety during use. The handle is constructed with a thickness of 12.5mm (0.492 inches), providing a substantial feel without adding unnecessary bulk.

Ergonomics and Portability:

Every aspect of the XW-1011 has been designed with user experience in mind. The total length of the knife when opened is 157mm (6.18 inches), making it a formidable tool while still fitting comfortably in your hand. Weighing in at just 70.5g (2.49 oz), this knife is designed for everyday carry. The tip-up pocket clip adds to its convenience, ensuring that the knife is always within reach when you need it.

Lock Mechanism and Opening:

Safety is paramount with any folding knife, and the XW-1011 features a reliable liner lock mechanism. This lock provides confidence during use, ensuring the blade stays open and minimizing the risk of accidental closure. The thumb stud opening mechanism allows for quick and easy blade deployment with one hand, a crucial feature for situations where speed and efficiency are essential.

Customization and Minimum Order Quantity:

Shieldon takes pride in offering ODM services, allowing for customization to meet specific branding needs. The regular MOQ for the XW-1011 model is set at 1200 units, providing an excellent opportunity for businesses to add a signature folding knife to their product line.

Why Choose Shieldon?

With years of expertise in both manufacturing and trading, Shieldon stands as a reliable partner for OEM folding knives. By choosing the XW-1011 Folding Pocket Knife, clients are investing in a product that is backed by rigorous quality control, customer-focused design, and a commitment to excellence.

Conclusion:

The Shieldon OEM XW-1011 Folding Pocket Knife is more than just a tool; it is a statement of style, a testament to tactical functionality, and a reliable companion for daily tasks or outdoor adventures. This knife is designed to cater to discerning users who value quality and efficiency.

Embark on a journey of unparalleled craftsmanship with Shieldon’s XW-1011 Folding Pocket Knife. This model is poised to become an essential addition to any product lineup, offering end-users a fusion of form and function that only Shieldon can deliver. With customization options, a favorable MOQ, and the expertise of a seasoned Manufacturing & Trading Combo business, the XW-1011 is ready to carve out a market niche and drive customer satisfaction to new heights.

The folding knife is an essential tool for many, serving as a trusted companion for everyday tasks, outdoor expeditions, or self-defense. Understanding the basic knowledge of your Everyday Carry (EDC) folding knife not only enhances its performance but also extends its lifespan. Here we will explore the essentials of maintaining your EDC folding knife and clarifying different knife steels for various scenarios.

Maintaining Your EDC Folding Knife

Regular maintenance of your folding knife is pivotal to ensure it remains in optimal condition. Here’s how to keep your EDC sharp, safe, and sturdy:

Clarifying Different Knife Steels for Scenario Uses

Knife steels vary widely in terms of hardness, toughness, corrosion resistance, and ease of sharpening. Here’s a basic guide to some common steel types and their ideal uses:

When selecting a knife steel, consider the primary use of your EDC knife. For general everyday tasks, a good quality stainless steel offers a balance of performance and ease of maintenance. If you’re expecting to put your knife through more rigorous paces, consider a high-carbon or tool steel, keeping in mind that these will require more attentive care.

결론

Your EDC 접는 나이프 is a tool of personal expression as much as it is a utility. By maintaining your knife properly and understanding the different types of steel available, you can ensure that your folding knife is always ready and reliable. Whether for everyday tasks, survival scenarios, or precision cutting, the right care and knowledge will keep your blade sharp and your tasks effortless. Remember, a well-maintained knife is a lifelong tool, and knowing your steel is the cutting edge of knife mastery.

OEM 나이프 프로젝트의 모든 단계에서 도움을 드릴 준비가 되어 있습니다. 귀하의 문의 사항과 예산을 보내주시면 이내 연락드리겠습니다. 24 시간.