For anyone who is looking to purchase a folding knife, one of the most important aspects to consider is its locking mechanism.

Different knives utilize different types of locks, such as frame locks, liner locks, back locks, and compression locks.

In this article, we’ll provide a comparative analysis of these four kinds of locks so that you can make an informed decision when choosing your next folding knife.

We’ll look at the pros and cons of each type of locking mechanism in order to help you decide which one best suits your needs.

Characteristics of Framelock

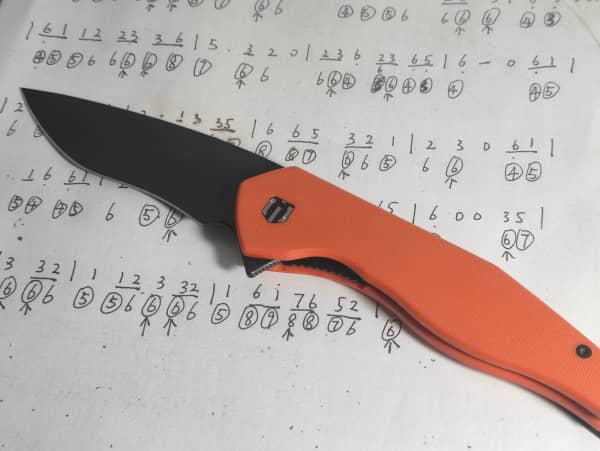

Framelock (also known as frame lock) is a locking mechanism commonly found in one-handed folding knives.

Unlike other types of locks, frame lock knives feature a solid frame that also acts as the handle of the knife. When the blade is opened, a portion of the frame is pressed against the back of the blade, effectively preventing it from closing.

One of the advantages of a frame lock is its strength and durability. The frame is made from a single piece of metal, which means that it is less likely to break or become loose over time.

Additionally, this type of lock is easy to manipulate with just one hand, which makes it ideal for outdoor enthusiasts who need to access their knives quickly.

However, there are also some drawbacks to using a frame lock knife. Because the lock is integrated into the frame, it can be challenging to disengage the lock if not done correctly.

Plus, the hinge pin of this type of knife can wear down much faster than other types of locks, requiring more frequent maintenance.

When selecting a knife with a frame lock mechanism, it’s essential to prioritize the quality of the lock and the materials used in the knife.

You should also consider your personal preferences and how you plan to use the knife.

Characteristics of Liner Lock

The liner lock is another common locking mechanism found in folding knives.

Similar to the frame lock, a liner lock knife features a liner inside the handle that is pushed to the side when the blade is opened. This liner also presses against the back of the blade, keeping it in place.

When you close the blade, it moves the liner aside. Opening the blade creates space for the liner to move inside and hook below the end of the blade. You need to move the liner by hand to release and close the blade.

One of the benefits of a liner lock is the ease of use. It’s a simple design that doesn’t require a lot of skill or effort to manipulate, making it an excellent choice for everyday carry knives. Plus, the ease of use also means that it’s a faster-locking mechanism compared to other types of locks.

However, one of the main drawbacks is that it’s not as strong as other types of locks like the frame lock or the back lock.

A liner lock is only as strong as the liner, so if the liner is made from poor-quality material or isn’t machined correctly, it can fail.

Additionally, a liner lock can also be more challenging to disengage than other types of locks, especially for those with larger hands.

This is because the liner is inside the handle, so you have to reach in and push it to the side.

Characteristics of Back-Lock

Back-Lock is a reliable and secure locking mechanism used in many folding knives. Its design includes a spring-loaded lock bar located on the spine of the knife handle, which engages a notch on the tang of the blade, thus securing the blade in an open position.

The lock bar is released by pushing it down, which disengages the notch, enabling the blade to be folded back into the handle. This mechanism is very common for hunting, survival, and tactical knives as it provides a secure lockup under hard use.

One of the significant advantages of Back-Lock mechanisms is durability. The lock bar design, which holds the blade open, has no spring and relies merely on the locking mechanism to keep the blade in place.

That means you don’t have to worry about the spring failing or losing tension over time, making it a reliable mechanism that can withstand hard use.

The Back-Lock mechanism is also very user-friendly. It’s easy to access with one hand, allowing you to quickly open and close the blade as needed. And unlike other locking mechanisms, the

Back-Lock is very secure, preventing unintentional closing of the blade, making it an ideal choice for outdoor and survival activities.

One of the downsides to the Back-Lock mechanism is that it can be challenging to disengage with one hand if you’re wearing gloves or have wet hands.

It’s also not as smooth to disengage compared to other locking mechanisms like Frame and Liner-Lock, and it’s not as suitable for rapid open/close cycles.

Another potential drawback of the Back-Lock mechanism is that it’s positioned on the spine of the handle, which can make it more difficult to grip comfortably for users who prefer different holding positions.

How to Choose the Best Type of Locking Mechanism for Pocket Knives

1. Consider Your Personal Preferences

The first step to choosing the best locking mechanism for your pocket knife is to consider your personal preferences and how you plan to use the knife.

This will help you determine which type of lock would be most suitable for your needs.

2. Research Different Locking Mechanisms

Before making a decision, it’s important to research the different types of locking mechanisms available in order to understand their features and benefits.

Frame locks, liner locks, back locks, and compression locks are some examples of common locking mechanisms used in folding knives today.

3. Determine Durability & Security

Durability and security are two key factors when selecting a locking mechanism for your pocket knife so make sure that whichever one you choose is designed with high-quality materials that can withstand hard use or wear and tear over time.

Additionally, try out different models or brands in person if possible before making a purchase as this will give you an opportunity to test out each option’s performance firsthand

4. Take into Account Ease Of Use & Comfort

It’s also important to take into account ease of use and comfort when shopping around as well since these features directly affect how much enjoyment or frustration you’ll have while using the knife.

Shieldon’s OEM Capabilities

Shieldon is a reputable knife manufacturer with a diverse range of folding knives.

The company’s expertise in producing high-quality knives is widely recognized, and its OEM capabilities allow customers to customize knives to suit their specific needs.

Shieldon’s manufacturing process employs modern CNC machines and utilizes high-quality materials such as stainless steel and titanium.

The company offers a wide range of choices for blade types, handle materials, and locking mechanisms.

Additionally, Shieldon’s OEM team works closely with customers to ensure that each knife meets their specific needs and specifications.

Their OEM capabilities ensure that customers can create unique, high-quality knives that are perfect for their intended use.

Click to have more Shieldon OEM EDC knives and tools fun.

Shieldon、Facebook、Instagram、YouTube、Twitter、Pinterest