I doubt many would consider the folding knife to be one of the greatest developments in the history of edged tools.

Over the years, manufacturers have devised many methods of opening and securing blades, some fairly simple, others quite unique and complex.

Assuming you’re buying a knife that you can use, rather than one you’re buying just for aesthetics, the mechanism used in the design should be a factor in your buying decision. If a knife is awkward to open and close, chances are it won’t be carried very often.

Below are some of the more popular cutting styles.

Open method

- Nail scratches

This is probably the most common feature, and one that most of us have in our early knife collections. This is simple. There is a small groove along the ridge of the blade.

To open the knife, you grab that point on the blade and open it. This basic design has several advantages. Structurally, this is the cheapest.

Nail scoring is simple and has been used for many years.

It’s also very safe since it usually requires two hands to open the knife. However, this is also its downside, as it is very difficult, though not impossible, to open such a knife with one hand.

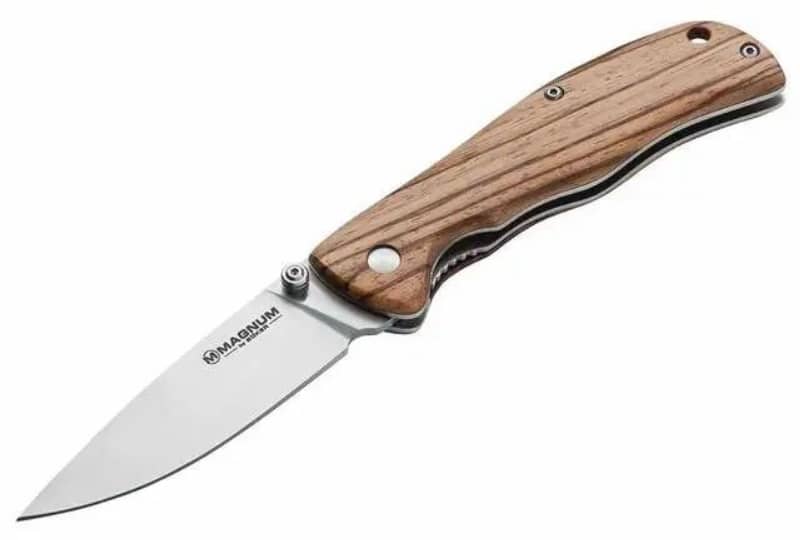

- Thumb stud

Knives with thumb studs became popular in the 1980s, although they were available before then, as I recall. You can even buy studs to attach to pocketknives that don’t come with studs yet.

The idea is basically to take a regular slide-joint knife and make it easy to open with one hand. You simply push the stud with your thumb, rotate the blade up, and open.

Thumb studs became very popular in the 1980s and are still used today.

Knife spikes are usually right-handed or left-handed, although some folding knives will have a spike on either side of the spine. “When you hold the knife in your hand, the movement is instinctive and effortless.”

- Thumb hole

Primarily a Spyderco design, which is a variation on the thumbnail idea. The knife is designed with a large hole along the spine. The spine itself curves upwards to make room for this feature.

One of the Spyderco’s signature features is the thumbhole on the spine of the blade.

In operation, it works like a thumb tack, but instead of pushing on a small metal outcrop, it pushes on the inside of the hole in the blade. This design is flexible.

- Fins

With a smooth knife action, the fins can open as fast as an automatic knife. When the knife is closed, something like a small lever is raised along the back of the handle, near the pivot. Pulling that lever with one finger swings the blade into place.

Fin open knives are very popular, and they open as fast as automatic knives.

When you hold a knife, the action is instinctive and effortless. As a bonus, when the knife is open, the flipper becomes a small gauntlet.

- Automatically

It may be a button or a slider, but when it is activated, the spring action is released and the blade goes into position. You’ll often find this slide on OTF cars, while the button is more common on switchblade type knives.

An example of an automatic knife

While laws are becoming more lenient in some areas, it’s worth taking the time to verify the legality of an automatic pistol before you throw it in your pocket and head to work.

- Auxiliary opening

This is number 71 from Great Eastern Tableware. This is a classic design slip joint knife.

The Emerson Wave is the shape of the hook on the top of the blade, and when you pull the knife out, it hooks into your pocket, opening the knife open.

It’s kind of like an automatic light. You need to initiate the movement of the blade, say via a thumb post, and once the blade reaches a certain point, it automatically pops open.

lock method

- Back lock

Many of us had a lockback knife or two in our youth, usually a Buck 110 or a copy or clone of it. When the blade is open, the rocker arm locks into a notch on the bottom of the blade, securing it in place. Pushing the back lock moves the arm out of position and allows the blade to fold shut.

The Buck 110 is a lockback knife. when the blade is open

- Liner lock

In this very common model, a tensioning rod inside the knife slides into place under the blade when it snaps into the open position. It stays there, keeping the blade secure until you manually push it aside and close the blade. This can be a very safe mechanism, depending on how well the rod engages the blade.

A wire lock uses a thin metal rod that wedges into place under the blade when the knife is opened. Move it aside with your thumb or finger to close the cutter.

- Frame lock

The frame lock has a piece of metal that fits under the blade of the folding knife. But in this case, it’s part of the frame, not the padding.

This is very similar to a linear lock. The difference is that the locking bar is not inside the liner, but part of the actual frame of the knife. This locking mechanism was invented by Chris Reeve of Chris Reeve Knife Company.

- Button lock

Typically found on automatic knives, a push button lock consists of a cylinder of sorts that rests on the bottom of the opened blade. To close the knife, you press the button, which slides a cutout section of the cylinder under the blade, allowing it to fold shut.

The button lock moves the cylinder inside the knife, which then allows the knife to close.

There are many proprietary mechanisms on the market, often brand-specific, such as the ring lock on Opinel folding knives.

The important thing to consider when buying a folding knife is how you are going to use it and how that translates into the on/off mechanism you find most useful. Having at least a basic understanding of how each knife opens and closes can help you make a more informed choice in this regard.

For example, if you’re looking for a pocketknife that can be used as a defensive weapon in a pinch, you’ll want something that can be opened with one hand. If you’re going to be doing any heavy work with this knife, you’ll want the strongest locking option you can find.

Click to have more Shieldon EDC knives and tools fun.