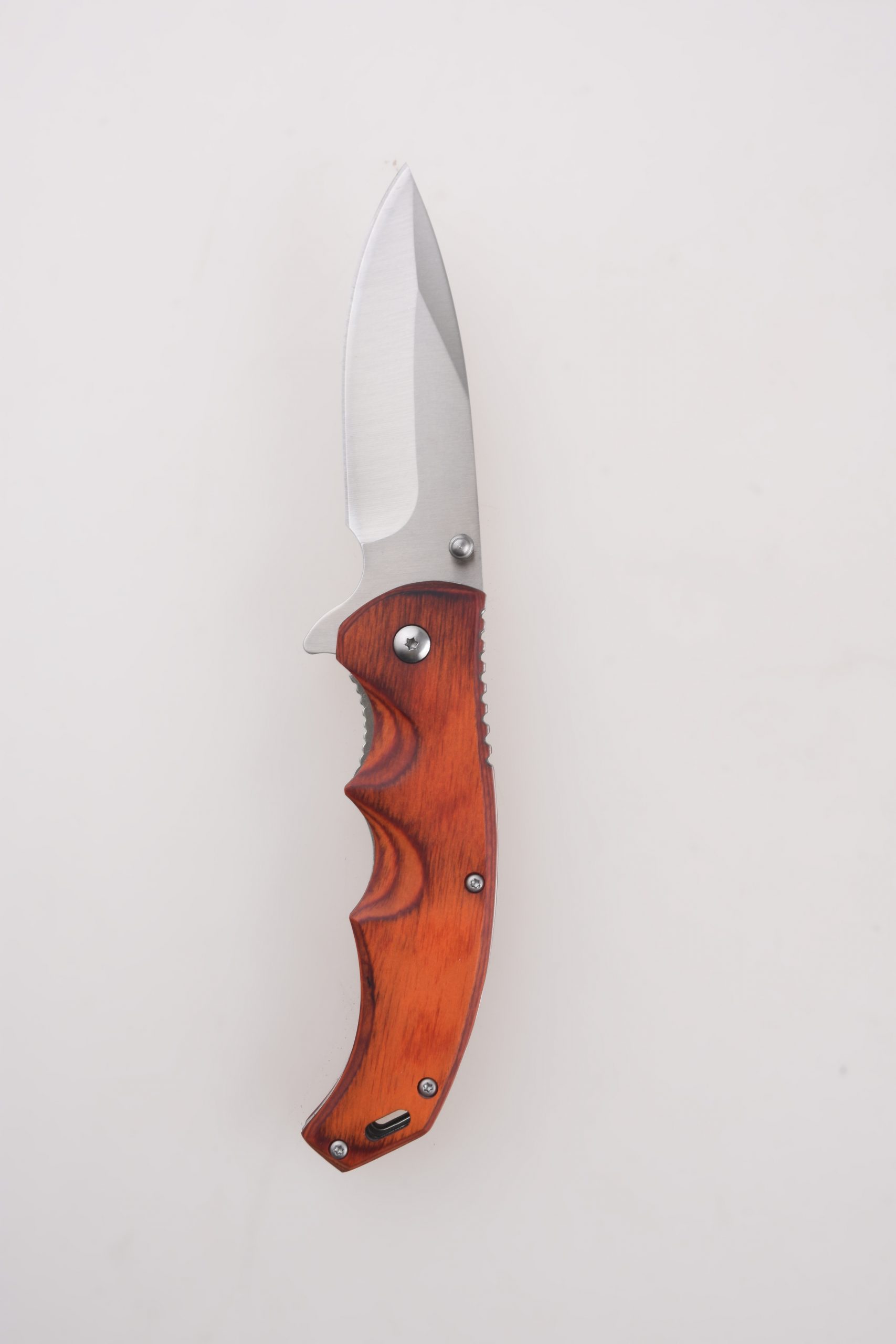

Item NO.: FR-0514

Item segment: Folding knife

Blade material: 3Cr13

Handle material: Color wood

Blade HRC: 50-52

Blade thickness: 0.106” / 2.7mm

Blade length: 3.46” / 88mm

Handle thickness: 0.642” / 16.3mm

Total length: 8.19” / 208mm

Weight: 4.62 oz / 131g

Blade style: Drop point

Handle color: Wooden

Pocket clip: Tip-down

Lock mechanism: Liner lock

Open way: Flipper + thumb stud

Blade finish: Satin

Blade grind: Flat

ODM Regular MOQ: 1200

Remark: Can make a slip-joint in the pivot

In the world of precision-crafted folding knives, the discerning enthusiast seeks a blend of aesthetic beauty, tactile pleasure, and unwavering functionality. The FR-0514 by Shieldon is a testament to this trinity of excellence. This knife is not just a tool; it’s an extension of the carrier’s personality, embodying a sense of timeless craft in its sleek design and robust build. Delve into the specifications of this folding knife, and you’ll find a product that offers elegance without sacrificing utility.

Product Overview

The FR-0514 item is part of Shieldon’s esteemed folding knife segment, appealing to both the seasoned collector and the practical user. It’s crafted with the ultimate attention to detail, reflecting Shieldon’s commitment to quality and performance.

Blade Excellence

At the heart of the FR-0514’s performance is the blade, forged from 3Cr13 stainless steel, known for its balance of hardness and resistance to corrosion. The metal composition ensures an HRC (Rockwell Hardness Scale) of 50-52, offering durability and ease of sharpening. With a thickness of 0.106 inches (2.7mm), the blade provides a sturdy backbone for the drop-point style, a versatile choice known for its strength and control.

The blade length of 3.46 inches (88mm) strikes the perfect balance between utility and portability. It’s finished with a satin sheen that enhances its elegant appearance while minimizing glare. Furthermore, the flat grind of the blade ensures a sharp and consistent edge, ideal for a variety of cutting tasks.

Handle Design

Encasing the blade is a handle material of color wood, a choice that imbues each knife with a unique pattern and warm, natural feel. The wooden handle not only adds an element of rustic charm but also provides a secure grip. Its thickness of 0.642 inches (16.3mm) allows for a comfortable hold, making the knife a suitable companion for extended use.

Functionality and Features

The total length of the knife when opened is 8.19 inches (208mm), an optimal size for a wide range of tasks. Weighing in at 4.62 ounces (131g), the FR-0514 provides a substantial feel in the hand without being cumbersome.

Ease of use is a hallmark of this model. The flipper and thumb stud opening mechanisms afford quick and smooth deployment of the blade, a crucial feature for those who need rapid access to their knife. For added versatility, Shieldon offers an option to incorporate an assist-spring in the pivot, enhancing the knife’s opening efficiency.

Safety and Security

Safety is paramount in the design of the FR-0514. The liner lock mechanism secures the blade firmly in place when open, providing confidence during use and preventing accidental closure. Additionally, the tip-down pocket clip ensures that the knife can be carried securely and discreetly, always within reach for when the need arises.

Aesthetic Touches

Aesthetic elements are not overlooked in the FR-0514. The lanyard hole at the pommel end not only adds a functional carrying option but also serves as a platform for personalization. Users can attach beads, cords, or tags to make their knife truly their own.

Customization and Collaboration

True to Shieldon’s Manufacturing & Trading Combo ethos, the FR-0514 is available for OEM (Original Equipment Manufacturer) services. This allows for customization to meet specific branding requirements or to cater to particular market trends. The minimum order quantity for ODM (Original Design Manufacturer) is set at 1200 units, a testament to Shieldon’s capacity to handle both large-scale production and individualized detail.

Quality Assurance

Every aspect of the FR-0514 reflects Shieldon’s unwavering dedication to quality. From the selection of materials to the final inspection processes, each knife is subject to rigorous standards. Clients can rest assured that they are receiving a product that is both reliable and refined.

Global Reach

Shieldon’s global presence ensures that the FR-0514 can be sourced and shipped efficiently to various markets, adhering to trade regulations and compliance standards. The company’s seamless logistics and supply chain management mean that clients can expect timely delivery and exceptional service.

Conclusion

The Shieldon FR-0514 folding knife is a masterclass in what it means to blend form with function. Its thoughtful design, premium materials, and practical features answer the call of those who demand quality without compromise. Whether it’s for everyday carry, outdoor adventures, or as an addition to a growing collection, the FR-0514 stands as a symbol of Shieldon’s dedication to crafting knives that are not only tools but treasured companions for life.

This OEM folding knife is more than a product; it’s a promise of durability, a statement of style, and a guarantee of satisfaction. Choose the Shieldon FR-0514, and hold in your hands the culmination of expert craftsmanship, a commitment to excellence, and a passion for delivering the very best to the world of folding knives.

A folding knife’s functionality, durability, and overall performance are largely dictated by the steel of its blade. Steel is not a singular substance but a complex alloy with a diverse chemical composition that can be tweaked and altered to create different properties. For the layperson or the burgeoning knife enthusiast, understanding the basics of folding knife steel is pivotal in selecting the right knife for your needs. This guide will provide an overview of the chemical composition of folding knife steel and how these elements affect a knife’s character.

Carbon Content: The Heart of Steel

The primary ingredient that transforms iron into steel is carbon. Carbon content is crucial—it significantly affects hardness, edge retention, and the ability to achieve a fine edge. In general, higher carbon content (typically above 0.5%) means harder steel, which translates into better edge retention but at the risk of brittleness. Popular high carbon steels like 1095 are renowned for their sharpness and are often used in survival knives.

Chromium: The Corrosion Resistor

Chromium is added to steel to increase corrosion resistance, hence the term “stainless steel,” which contains at least 10.5% chromium. Not only does it protect against rust, but it also enhances hardness and tensile strength. Austenitic steels such as 304L are low carbon and high chromium steels known for their toughness and resistance to corrosion, making them suitable for knives that are frequently exposed to harsh environments.

Molybdenum and Vanadium: The Toughness Enhancers

Molybdenum and vanadium are often added to improve the strength and toughness of the blade, as well as to enhance resistance to wear and temperature-induced stress. Steels like VG-10 and S30V have a good balance of these elements, resulting in knives that are durable, retain an edge well, and resist wear over time.

Nickel: The Toughness Contributor

Nickel is added in smaller amounts to improve toughness and corrosion resistance. It can be found in some high-end knife steels, helping to make blades that are both strong and durable, capable of withstanding heavy use without damage.

Manganese and Silicon: The Unsung Heroes

These elements are typically found in small quantities in knife steel. They contribute to the overall strength and hardness of the blade. Manganese aids in the steel hardening process, while silicon boosts flexibility.

Tungsten and Cobalt: The Refiners

Tungsten and cobalt are not as common but serve to further refine the steel’s properties. Tungsten increases hardness and resistance to heat, allowing a blade to maintain its edge at high temperatures. Cobalt, while expensive, increases overall strength and hardness.

Making Comparisons: Popular Knife Steels

Wrapping Up: The Steel Tells the Story

When selecting a folding knife, it’s essential to consider what tasks the knife will perform. High carbon steels might suit someone who requires a razor-sharp edge and is willing to maintain it, while stainless steels are better for those seeking low maintenance and corrosion resistance. A steel like VG-10 or S30V strikes a balance between these attributes, offering a versatile blade for various uses.

The chemical composition of folding knife steel is a rich tapestry that tells the story of a blade’s potential. By understanding these elements and their contributions, you can make an informed decision about which knife will serve your purposes best. Whether you’re a casual user or a knife aficionado, acknowledging the subtle complexities of steel chemistry is the first step towards appreciating and choosing your ideal folding knife.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.