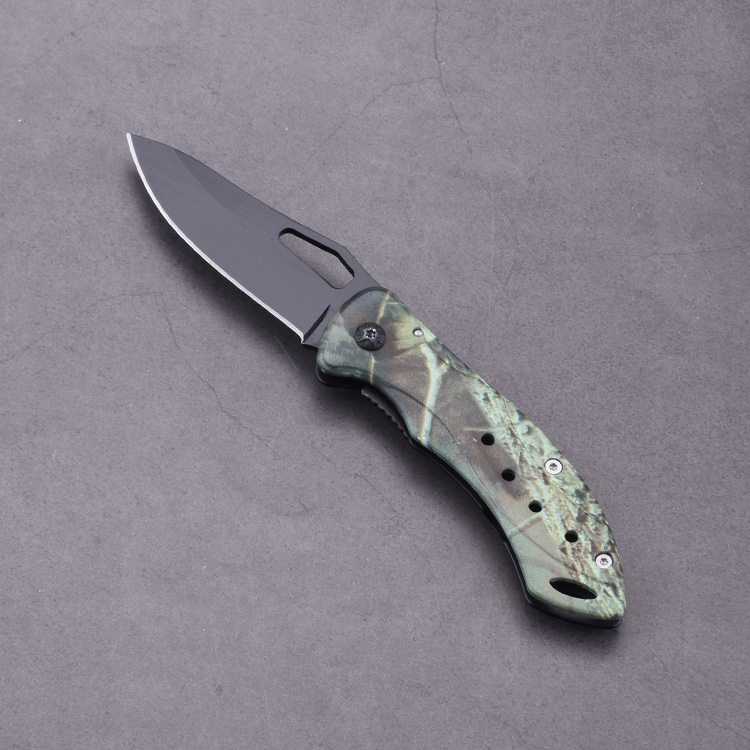

Item NO.: XW-1015

Item segment: Folding knife

Blade material: 3Cr13

Handle material: Anodized aluminum

Blade HRC: 50-52

Blade thickness: 2.8mm/0.11”

Blade length: 73mm/2.87”

Handle thickness: 13mm/0.512”

Total length: 164mm/6.46”

Weight: 67g/2.36 oz

Blade style: Clip point

Handle color: Camo

Pocket clip: Tip-up

Lock mechanism: Liner lock

Open way: Hole

Black finish: Blackened

Blade grind: Flat

ODM Regular MOQ: 1200

When it comes to equipping oneself with a reliable, stylish, and functional folding pocket knife, the details matter. The Shieldon XW-1015 is designed with meticulous attention to detail, blending form and function into a compact tool that is as robust in performance as it is in appearance. This description will serve as a comprehensive guide to understanding the product specifications and how it fits into the Shieldon Manufacturing & Trading Combo business’s commitment to excellence.

Design and Utility: The Hallmarks of Shieldon Products

The Shieldon XW-1015 sits at the intersection of design innovation and practical utility. It is an embodiment of what discerning users seek in a folding knife: a dependable tool that upholds aesthetic integrity without compromising on performance. The folding knife segment has seen a surge of interest from outdoor enthusiasts, DIY hobbyists, and everyday carry (EDC) aficionados, and the XW-1015 caters precisely to these dynamic applications.

Blade Mastery: The Core of Shieldon Knives

Central to the knife’s prowess is its blade, forged from 3Cr13 stainless steel. This material is chosen for its balance of toughness, corrosion resistance, and ease of sharpening. The blade hardness rating of 50-52 HRC ensures that the knife retains its edge through repeated use while still allowing for straightforward maintenance.

With a blade thickness of 2.8mm (0.11”) and a length of 73mm (2.87”), the XW-1015 offers resilience and precision in cutting tasks. The clip point blade style is a testament to its versatility, providing a sharp point for piercing and a long cutting edge for slicing. A blackened finish enhances corrosion resistance and reduces glare, making the knife discreet and tactically suitable for all scenarios.

Ergonomic Excellence: Sophistication in Every Grip

The anodized aluminum handle of the XW-1015 is crafted not only for durability but also for ergonomic comfort. The anodization process not only imparts the handle with its distinctive camo color but also reinforces the aluminum’s natural resistance to wear and corrosion. The handle’s thickness of 13mm (0.512”) promises a secure and comfortable grip, essential for control and safety during use.

Compact Agility: A Profile of Portability

With an overall length of 164mm (6.46”) when open, and a weight of just 67g (2.36 oz), the XW-1015 epitomizes portable convenience. It is designed to be a discreet companion for daily tasks, easily carried with its tip-up pocket clip, ensuring that it is always within reach when needed.

Intuitive Operation: Streamlined Accessibility

The knife features a liner lock mechanism, a popular choice for EDC knives due to its reliability and ease of one-handed operation. Deployment is equally streamlined, featuring an open hole that allows for quick and effortless blade engagement.

Precision Ground: A Blade Built for Performance

The blade’s flat grind is a clear indication of Shieldon’s dedication to cutting efficiency. This grind type is ideal for general-purpose use and is appreciated for its strength and ability to take on a variety of materials, from packing tape to tougher outdoor challenges.

Strategic Collaboration: Shieldon’s OEM/ODM Advantage

As with all of Shieldon’s offerings, the XW-1015 is available for OEM (Original Equipment Manufacturer) integration, allowing businesses to brand and market this knife under their own name. This partnership is a hallmark of Shieldon’s commitment to supporting clients’ business aspirations with high-quality products that drive customer satisfaction and retention.

Additionally, Shieldon’s ODM (Original Design Manufacturer) services empower clients to modify or enhance existing designs, further tailoring the product to meet specific market demands or to carve out a unique niche within the competitive knife industry. The regular MOQ (Minimum Order Quantity) for such customization stands at 1200 units, a testament to Shieldon’s flexibility and scalability in accommodating diverse business needs.

The Shieldon Seal of Trust

Clients engaging in procurement from Shieldon can do so with the assurance of transparency and quality. Every product, including the XW-1015, is subjected to stringent quality controls, ensuring that each knife not only meets but exceeds industry standards and customer expectations.

Conclusion: A Cut Above the Rest

The Shieldon XW-1015 folding pocket knife encapsulates the essence of what makes a cutting tool exemplary. It is the synthesis of durable materials, user-centered design, and refined aesthetics. The flexibility in MOQ for OEM/ODM projects opens the door for businesses of varying scales to offer a premium product that aligns with their brand identity and market strategy.

In the complex tapestry of global trade and local market demands, the XW-1015 stands as a beacon of precision engineering and flexible partnership. Shieldon invites businesses worldwide to explore how this folding knife can become a cornerstone of their product offerings, promising a partnership that cuts through complexity to deliver simplicity and satisfaction in every slice.

An Everyday Carry (EDC) folding knife is a versatile and reliable tool that many people consider an essential part of their day-to-day gear. Whether you’re a seasoned outdoorsman, a dedicated crafter, or just someone who appreciates the practicality of a good knife, understanding the basics of EDC folding knives is invaluable. This guide will delve into the art of selecting and utilizing an EDC folding knife and clarify the various steel types for different scenarios.

Mastering Your EDC Folding Knife

Understanding how to operate your folding knife safely and effectively is the first step to truly ‘playing’ it as an EDC tool. Here are some essentials:

Different Knife Steels for Different Scenarios

The steel of an EDC folding knife’s blade determines its strength, durability, and how well it holds an edge. Here’s a brief rundown on different steel types to help you choose the right one for your needs:

Selecting the right steel type for your EDC folding knife depends on what types of tasks you expect to encounter most frequently. If you’re looking for an all-rounder, stainless steel varieties like 8Cr13Mov offer a good mix of durability and ease of maintenance. For more heavy-duty or specialized use, consider tool steel options that cater to specific needs.

Conclusion: Your EDC Folding Knife Companion

An EDC folding knife is not just a tool; it’s a daily companion that stands ready to conquer tasks big and small. By practicing safe usage, maintaining your knife, and selecting the right steel for your lifestyle, you ensure that your folding knife is more than just a utility—it becomes an extension of your own capability and resourcefulness.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.