Item NO.: FL-O.T.F

Item segment: O.T.F.

Blade material: 3Cr13

Handle material: Zinc alloy

Blade HRC: 32-34

Blade thickness: 2.8mm/0.11”

Blade length: 85mm/3.35”

Handle thickness: 12.03mm/0.474”

Total length: 213mm/8.39”

Weight: 137.5g/4.85 oz

Blade style: American tanto

Handle color: Black

Pocket clip: Tip-down

Open way: Thumb slide

Black finish: Blackened

Blade grind: Flat

ODM Regular MOQ: 10

Remark: glass striker

When it comes to equipping oneself with a reliable, rugged, and precision-engineered tool, the choice of a pocket knife is paramount. Shieldon Manufacturing & Trading Combo introduces the FL-O.T.F OEM O.T.F. Pocket Knife, a state-of-the-art cutting instrument that combines practicality with a sleek aesthetic. This knife is more than just a tool; it’s a testament to Shieldon’s commitment to delivering exceptional quality and performance in every product.

Product Overview

Introducing the FL-O.T.F, a meticulously crafted O.T.F. (Out-The-Front) pocket knife that embodies the essence of practical design and durability. Designed for the discerning user, the FL-O.T.F is a blend of premium materials, superb functionality, and aesthetic sophistication.

Blade Excellence

The heart of the FL-O.T.F lies in its formidable blade, constructed from high-grade 3Cr13 stainless steel, known for its excellent strength and resistance to corrosion and wear. The blade material strikes a balance between maintaining a sharp edge and offering easy resharpening. With a hardness rating of 32-34 HRC, it ensures a resilient edge that can withstand rigorous use.

The American tanto blade style affords the knife a tactical edge, providing a strong point for piercing and a flat grind that ensures versatility for slicing tasks. At a thickness of 2.8mm (0.11 inches), the blade is robust enough to handle demanding activities without compromising its slicing capabilities.

Handle Durability

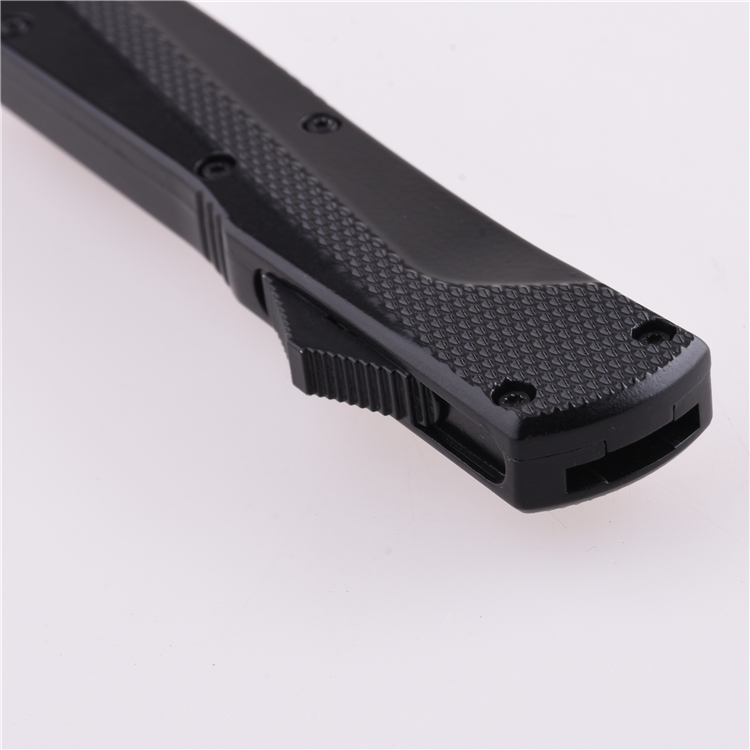

Encasing the robust blade is a handle crafted from zinc alloy, offering a sturdy grip that is both durable and lightweight. The handle’s black color imparts a sleek, inconspicuous appearance, making it suitable for a variety of settings. At a thickness of 12.03mm (0.474 inches), the handle provides a comfortable and secure grip for extended use without causing fatigue.

Compact Dimensions

With a blade length of 85mm (3.35 inches) and a total length of 213mm (8.39 inches) when fully deployed, the FL-O.T.F is designed for ease of carry while providing ample size for a wide range of cutting tasks. The knife’s weight, at 137.5g (4.85 oz), ensures it is substantial enough to handle with confidence yet light enough for everyday carry.

User-Friendly Features

The FL-O.T.F comes equipped with a tip-down pocket clip, allowing for discreet and secure carry. The thumb slide offers a smooth and intuitive means to deploy and retract the blade with minimal effort, a crucial feature for quick access during critical moments.

The blade’s blackened finish not only adds to its tactical look but also minimizes reflections, making it an ideal tool for users who prefer to keep a low profile. The flat grind on the blade ensures it can be sharpened easily and maintains its edge through continued use.

Additional Functionality

Not merely satisfied with providing a cutting edge, the FL-O.T.F also incorporates a glass striker. This feature transforms the knife into a versatile survival tool, capable of breaking glass in emergency situations, making it an indispensable companion for outdoor enthusiasts, first responders, and tactical operators.

ODM Opportunities

Shieldon welcomes Original Design Manufacturer (ODM) collaborations with a Regular Minimum Order Quantity (MOQ) of only 10 units, demonstrating our commitment to supporting businesses of all sizes from startups to established brands. This flexibility enables our partners to develop and test their market with minimal risk and investment.

Shieldon’s Quality Assurance

With the FL-O.T.F, you are not just purchasing a knife; you are investing in a piece of Shieldon’s legacy of quality. As a holder of the ISO 9001 quality control system certification, Shieldon ensures that each FL-O.T.F knife undergoes a stringent and comprehensive quality assurance process. From raw material selection to final inspection, every step is meticulously monitored to uphold the highest standards of excellence.

Conclusion

The Shieldon FL-O.T.F OEM O.T.F. Pocket Knife is an embodiment of functional artistry and rugged durability. It is a tool that resonates with the needs of the modern user, offering a harmonious blend of utility, comfort, and style. For those who demand the best in their gear, the FL-O.T.F stands ready as a testament to Shieldon’s unwavering commitment to quality and performance. As you consider your procurement options, let the FL-O.T.F be the benchmark for excellence in your product lineup. With Shieldon, you are not just sourcing a product; you are forging a partnership that is sharpened on the whetstone of reliability and honed to perfection.

Out-The-Front (O.T.F.) knives are a fascinating segment of the knife community, known for their unique deployment mechanism that allows the blade to extend and retract through the front of the handle with the push or pull of a button or slider. Whether you’re a knife enthusiast, a collector, or someone interested in the mechanics of everyday carry tools, understanding the structure of an O.T.F. knife is fundamental. Here’s a guide that breaks down the basic anatomy of an O.T.F. knife to provide you with foundational knowledge.

Core Components of an O.T.F. Knife

Internal Mechanism

The internal mechanism is what sets O.T.F. knives apart from other types of knives. It consists of several key elements working in harmony to facilitate the smooth action of the blade:

Safety Features

Given the nature of their deployment, O.T.F. knives are built with safety features to prevent accidental deployment. These features include:

Maintenance and Care

O.T.F. knives require regular maintenance to ensure their longevity and functionality. This involves cleaning the track, lubricating the moving parts, and occasionally adjusting the tension of the springs. Proper care ensures that the knife will perform reliably each time the blade is deployed or retracted.

Conclusion

An O.T.F. knife is more than just a cutting tool; it’s a marvel of design and engineering. The intricate mechanism that allows for the swift and effortless extension and retraction of the blade is the result of careful craftsmanship and precise assembly. For anyone interested in O.T.F. knives, whether for practical use or as collectibles, appreciating the internal workings is essential. Understanding the structure of an O.T.F. knife not only helps in choosing the right knife but also in maintaining it properly for years of reliable service.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.