Item NO.: YD03

Item segment: Hunting knife draft

Blade material: Pending

Handle material: Pending

Blade HRC: Pending

Size and weight: Pending

Blade style: Tanto point

Handle color: Pending

Sheath: K-sheath

Blade finish: Pending

Blade grind: Pending

ODM Regular MOQ: Pending

Remark: K-sheath

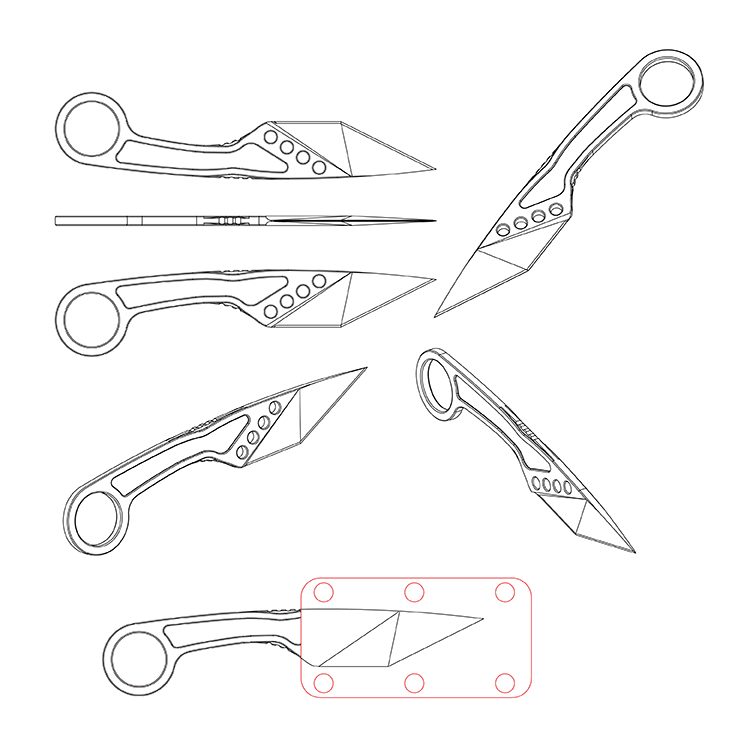

The Shieldon YD03 neck knife draft presents the emboldened contours of a modern tool designed to cater to the discerning needs of the 2023 EDC (Everyday Carry) enthusiast. With its skeletonized handle and classic tanto point blade, this draft outlines a knife that’s as much about form as it is about function. The YD03 is poised to be an essential addition to any outdoor or tactical gear lineup, offering a balance of compact utility and robust performance. Here is a comprehensive draft description based on the preliminary product specifications provided, capturing the vision of this cutting-edge design.

Item NO.: YD03

The YD03 stands as a beacon of Shieldon’s commitment to innovation and quality. It is envisioned as a neck knife that marries traditional design elements with contemporary efficiency, a testament to Shieldon’s Manufacturing & Trading Combo business’s prowess.

Item Segment: Hunting Knife Draft

Positioned within the competitive hunting knife segment, the YD03 draft is aimed at those who demand a knife that can keep pace with their adventurous spirit. It’s designed to be a versatile partner in various scenarios, from intricate bushcraft to game processing, without compromising its status as a stylish EDC item.

Blade Material: Pending

The choice of blade material for the YD03 is pending, with the intention to adopt a substance that withstands rigorous use while maintaining a sharp, enduring edge. Future selections may range from high-carbon steel for unparalleled sharpness to corrosion-resistant stainless steels for longevity and ease of maintenance.

Handle Material: Pending

While the design showcases a skeletonized handle for reduced weight and a distinct aesthetic, the final material remains open to client preferences. The selection process will consider factors such as durability, grip, and overall balance to ensure that the YD03 excels in both form and utility.

Blade HRC: Pending

The blade’s hardness rating (HRC) is yet to be determined. This critical spec will be decided in consultation with the client, allowing for customization based on the blade’s intended usage. The final HRC will ensure that the YD03 offers the perfect compromise between resilience to wear and ease of sharpening.

Size and Weight: Pending

The dimensions and weight of the YD03 are crucial in defining its role as a neck knife. The draft leaves room for adjustments to meet the sweet spot between a lightweight profile for comfortable wear and sufficient heft for practical application. The eventual size will reflect the knife’s intended use, user comfort, and portability.

Blade Style: Tanto Point

A defining feature of the YD03 is its tanto point blade, a style inspired by traditional Japanese swords known for their strength and puncturing capability. This blade style is highly favored for tactical applications but is also well-suited for precision cutting tasks, making it a versatile choice for an EDC knife.

Handle Color: Pending

The color of the handle will be tailored to the brand’s specifications, allowing for personalization that complements the knife’s function and design. Whether the choice is a classic black for tactical users or a bright color for quick identification in an outdoor setting, the color will be an extension of the brand’s identity.

Sheath: K-sheath

Every YD03 neck knife is planned to be accompanied by a K-sheath, recognized for its durability and ease of access. The sheath is designed to secure the knife snugly while allowing for quick deployment, a necessity for any reliable EDC tool.

Blade Finish: Pending

The blade finish for the YD03 remains flexible, with options ranging from a matte non-reflective finish suitable for tactical use to a polished surface for those who favor a more refined look. The chosen finish will enhance the knife’s physical properties while also considering the aesthetic appeal.

Blade Grind: Pending

The blade grind—whether hollow, flat, or convex—is yet to be finalized. This aspect will be intricately planned to align with the knife’s intended cutting tasks and overall design, ensuring that the YD03 is not only sharp and durable but also a reflection of the brand’s expertise in knife making.

ODM Regular MOQ: Pending

With an understanding that businesses have varying demands, the minimum order quantity for the YD03 will be determined based on the specific needs of the client. Whether the project requires a small batch of custom-made knives or a larger scale production, Shieldon is ready to accommodate with flexible MOQ options.

Remark: K-sheath Extra Cost

It should be noted that the inclusion of a K-sheath, while adding value to the overall product, may result in additional costs. The investment in a high-quality sheath, however, underscores the commitment to providing a complete and polished knife package.

Conclusion

The YD03 neck knife draft is an open blueprint, an invitation for collaboration between Shieldon and brands looking to forge a unique product that resonates with quality, functionality, and style. As a draft, it is a starting point, flexible and ready to be adapted to the intricate needs and desires of clients who are eager to make their mark in the world of EDC and hunting knives.

This draft, with all its pending specifications, represents a partnership opportunity. It signals Shieldon’s readiness to transform this preliminary vision into a tangible product that embodies the client’s brand ethos and market ambitions. With Shieldon’s OEM/ODM services, the journey from conception to production is a shared venture, culminating in a knife that is not just a tool, but a manifestation of the brand’s commitment to excellence and distinction in the cutlery industry.

In the dynamic world of custom knife manufacturing, the attention to detail often distinguishes a remarkable product from a mundane one. A knife is not just a blade and handle—it is a cohesive assembly of components that each play a vital role in the final product’s functionality and aesthetic. Shieldon, with its comprehensive OEM/ODM folding knife project service, understands this intricate interplay and extends an array of extra components to enhance the custom fixed knife assembly. From precision-engineered screws to custom-designed sheaths and functional lanyards, Shieldon’s additional offerings ensure that every knife is a masterpiece of craftsmanship and utility.

The Core of Customization

Customization is at the heart of Shieldon’s service, offering clients the ability to tailor every aspect of their knife project. A knife’s design, materials, and ergonomics are all essential. Still, the additional components such as screws, sheaths, and lanyards contribute significantly to the overall quality and user experience. These seemingly minor details can dramatically impact the knife’s appeal and practicality, making Shieldon’s extra component offerings an integral part of the customization process.

Precision Screws for Secure Assembly

The screws are the unsung heroes of a knife’s structural integrity. They hold the knife together, and their quality can mean the difference between a knife that feels solid and one that feels flimsy. Shieldon offers a selection of premium screws made from high-grade materials designed to withstand the rigors of repeated use. Clients can choose from various sizes, threads, and head styles to match their knife design and ensure a snug, seamless fit that maintains the knife’s sleek profile.

Custom-Designed Sheaths for Protection and Portability

A sheath is more than just a cover; it is an essential companion to a fixed knife that offers protection to the blade and user while enhancing portability. Shieldon’s sheath options are crafted with care and precision, from durable materials such as leather, Kydex, or nylon. Each sheath design considers the knife’s specific dimensions and user needs, ensuring a perfect fit that is both secure and accessible. Whether the focus is on stealth, quick deployment, or aesthetic complement to the knife, Shieldon’s custom sheaths meet the mark.

Lanyards for Added Functionality and Flair

Lanyards may seem like a simple addition, but they can significantly enhance a knife’s functionality and style. They make retrieval easier, allow for additional carry options, and can be a canvas for personal expression. Shieldon provides a selection of lanyard materials such as paracord, leather, or synthetic fibers, which can be customized in color and weaving patterns to align with the knife’s design and the client’s brand identity.

Collaborative Design Process

At Shieldon, the client is a co-creator in the design process. The team works closely with clients to understand their vision and translate it into every element of the knife, including the additional components. With state-of-the-art technology and an experienced design team, Shieldon ensures that each component is not only functional but also reflects the intended aesthetic of the final product.

Material Selection for Performance and Durability

Material selection is pivotal in the creation of extra components. Shieldon ensures that all offered materials—from the toughest stainless steel for screws to the most resilient synthetic fibers for lanyards—stand up to the demands of heavy use and environmental exposure. Clients can select materials based on their characteristics, such as corrosion resistance, tensile strength, or aesthetic qualities, allowing for a customized product that excels in both performance and longevity.

Quality Control for Consistency

Quality control is a constant at Shieldon, and extra components are no exception. Each screw, sheath, and lanyard is subject to rigorous inspection to ensure that they meet Shieldon’s high standards for quality and consistency. This attention to detail guarantees that the final product will not only look good but will also be reliable and durable.

Efficient Manufacturing for Timely Delivery

Shieldon’s integrated approach to manufacturing ensures that the production of extra components is as efficient as the knives themselves. By managing the entire process, from material sourcing to final assembly, Shieldon provides a seamless and timely delivery of completed knife projects, ensuring that clients can bring their products to market without unnecessary delays.

Sustainable Practices for a Better Future

In line with modern expectations, Shieldon embraces sustainability in producing extra components. By choosing eco-friendly materials and minimizing waste in the manufacturing process, Shieldon demonstrates a commitment to environmental responsibility that resonates with clients and end-users alike.

End-to-End Solutions for Brand Growth

Shieldon’s extra components are part of a comprehensive OEM/ODM service that provides end-to-end solutions for brands looking to grow and differentiate themselves in the marketplace. By offering a full spectrum of customization options, Shieldon empowers brands to create unique products that tell their story and fulfill their customers’ needs.

Conclusion

The essence of Shieldon’s OEM/ODM folding knife project service lies in its meticulous attention to the components that complement the knife’s core assembly. The provision of extra components such as screws, sheaths, and lanyards is a reflection of Shieldon’s dedication to excellence in every detail. These components are not afterthoughts but integral elements of the knife’s design, contributing to a product that is sophisticated, functional, and tailored to the client’s specific requirements. By partnering with Shieldon, brands can rest assured that their custom knife projects will be handled with the utmost care and expertise, resulting in a product that truly stands out in form, function, and finish.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.