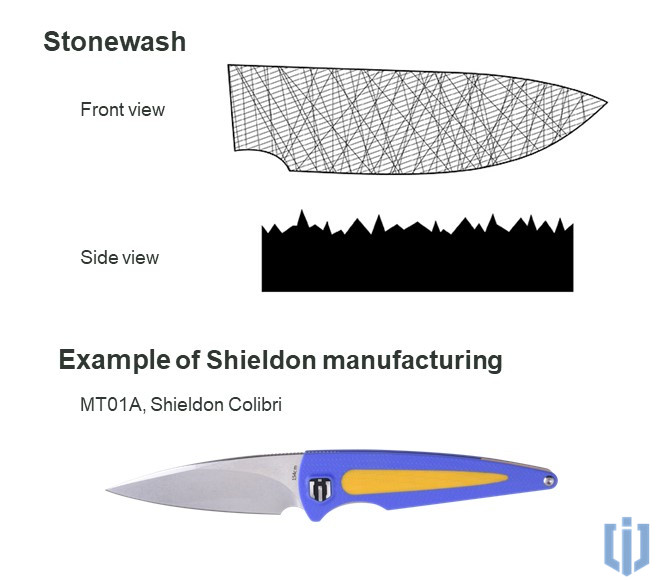

The stonewash blade finish is a highly favored surface treatment known for its remarkable benefits, making it an ideal choice for EDC knives and beyond. This finish involves subjecting the blade to a tumbling process with abrasive materials like ceramic stones or pebbles, resulting in a distinct, textured appearance. Stonewash finishes are celebrated for their outstanding durability, concealing minor scratches and providing a protective layer against corrosion. Additionally, the textured surface enhances grip, reducing the risk of accidental slips during use, which is invaluable for tasks requiring precision and safety. Beyond its functional advantages, the stonewash finish also contributes to the aesthetics of the blade, giving it a unique and rustic character. At Shieldon, we recognize the allure and practicality of the stonewash blade finish and offer a variety of stonewash options for EDC knives. Our expertise ensures that your knives not only look exceptional but also perform reliably in diverse real-world scenarios, enhancing both their appearance and functionality. With Shieldon as your OEM/ODM manufacturer, you can trust in the quality and versatility of the stonewash finish.

The stonewash blade finish has a long history that goes back to the beginning of blade making. It started out as a practical necessity, and the first blades had to be buried in sand and stone to make them last. As time went on, this practical method turned into the stonewash finish we know today, which is a way to combine form and function.

Abrasive materials, such as clay stones or rocks, are used in the stonewash process to get the desired rough look while also getting rid of surface defects. These historical facts and the use of rough materials show how tradition and innovation can work together in blade design, creating a product that is both useful and nice to look at.

At Shieldon, we proudly offer a diverse range of stonewash blade finish options, specifically tailored to enhance the quality and performance of your EDC knives and various cutting tools. Our commitment to excellence extends beyond surface treatment, as we provide a holistic solution for all your needs. Here’s what we offer.

Shieldon's team of experts stands ready to assist you in choosing the perfect stonewash finish, aligning with your preferences and requirements. Their invaluable insights ensure that your blades not only look exceptional but also perform optimally.

We understand the importance of budget-conscious decisions. Shieldon provides cost-effective stonewash options, allowing you to achieve the desired finish without breaking the bank.

Your vision matters. Shieldon offers customization options, including the choice of color and blade length, enabling you to create knives that truly reflect your unique style and purpose.

We uphold stringent quality control measures throughout the stonewash application process, ensuring that your knives and tools meet the highest standards in terms of both aesthetics and functionality.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.