SK-5 steel is a high-carbon steel commonly used in making pocket knives due to its balance of hardness and toughness.

It is known for its ability to hold a sharp edge, making it ideal for cutting tasks.

This guide aims to provide an overview of SK-5 steel, detailing its properties, advantages, and why it is a popular choice for both knife makers and users.

Understanding SK-5 steel helps knife enthusiasts make informed decisions when selecting their tools.

Overview of SK-5 Steel

SK-5 steel, also referred to as SK85, is a high-carbon tool steel that originates from Japan.

It has a carbon content of approximately 0.85%, contributing to its durability and strength.

The designation “S” stands for steel, and “K” means tool in Japanese, highlighting its primary use in crafting tools like hammers and saws.

Due to its chemical composition, which affects its hardness and wear resistance, SK-5 steel is often subjected to processes like quenching and tempering to achieve optimal mechanical properties.

After these processes, it typically reaches a hardness of around 59 HRC, making it suitable for both everyday and heavy-duty applications.

The properties of SK-5 steel are quite remarkable. It has a density of 7.84 g/cm³ and an annealing hardness of less than 207 HB, which indicates its ability to endure wear and tear.

In terms of performance, it also boasts high tensile strength, ranging from 460 to 930 MPa, depending on the finish of the steel.

This material is not only effective for knives, like the popular Cold Steel models but also finds applications in various mechanical parts where hardness and wear resistance are paramount.

Overall, SK-5 steel’s combination of hardness, good wear resistance, and versatility makes it a favored choice among knife makers and tool manufacturers alike.

Performance Characteristics of SK-5 Steel

Hardness and Sharpness

SK-5 steel is known for its impressive hardness, which helps keep the blade sharp for longer. Hardness is measured using the Rockwell scale, and SK-5 typically scores around 59 HRC.

This means that knives made from SK-5 steel can withstand heavy use without dulling quickly, making them ideal for tasks like camping, hunting, and woodworking.

For example, a pocket knife crafted from SK-5 steel can easily slice through ropes or carve wooden pieces without losing its edge, allowing users to perform various tasks efficiently.

The sharpness of SK-5 steel, along with its hardness, is why it’s popular with knife enthusiasts.

A sharp blade is important for clean cuts, and SK-5 steel keeps a fine edge that can be easily maintained.

This makes it great not just for outdoor activities but also for daily tasks in the kitchen or at home. A sharp SK-5 steel kitchen knife can simplify food prep, making it easy to slice vegetables and meats.

Toughness and Impact Strength

Toughness is a key feature of SK-5 steel, allowing it to absorb energy and handle shocks without cracking or breaking.

This quality is crucial for tools in challenging environments, like survival knives or camping gear, where drops or heavy impacts are common.

For example, an SK-5 steel knife can withstand the force of chopping wood or carving without damaging the blade. This toughness keeps the knife reliable and functional under pressure.

Alongside toughness, SK-5 steel has good impact strength, essential for tools facing sudden forces. This is particularly useful in construction or heavy-duty outdoor jobs.

A knife that withstands prying or digging without bending or snapping is invaluable.

SK-5 steel is often used in survival knives that endure rigorous use, staying intact when handling tough materials like branches or ropes during outdoor adventures.

Wear Resistance

Wear resistance is an important feature of SK-5 steel, making it suitable for tasks that involve cutting and chopping.

This characteristic helps the blade maintain its sharpness and shape over time, even when used on tough materials.

For instance, when using an SK-5 steel knife for outdoor activities like camping or hunting, the blade can cut through hard materials such as rope, wood, and even tough animal hides without wearing them down quickly.

Some key points about the wear resistance of SK-5 steel include:

- Durable Edge: The steel can withstand constant use, allowing it to maintain a sharp edge even after extended periods of cutting.

- Long-lasting Performance: SK-5 knives often last longer than those made from lower-quality materials, making them cost-effective over time.

- Versatile Applications: In addition to knives, SK-5 steel’s wear resistance makes it suitable for tools like saw blades and chisels, which also require durability during heavy use.

Corrosion Resistance

Corrosion resistance is an important characteristic of SK-5 steel, but it is not as strong as some other types of steel.

This means that if SK-5 steel is exposed to moisture and air for long periods without care, it can begin to rust.

To help prevent this, it’s essential to keep SK-5 knives dry after use and store them in a cool, dry place.

For example, if you finish using your SK-5 pocket knife while camping, make sure to wipe off any moisture and store it in a dry bag or case to maintain its quality.

While SK-5 steel may not have the higher corrosion resistance of stainless steel, it can still perform well in many situations.

For instance, if you are using an SK-5 knife for outdoor activities like fishing or hunting, simply rinsing it with fresh water and drying it off after each use can help prevent rust.

Applying a light coat of oil can also provide an extra layer of protection against the elements

Comparison of SK-5 with Other Steels

SK-5 Steel: A Balanced Choice

When it comes to selecting the right steel for your knife, SK-5 steel is often a noteworthy contender due to its advantageous blend of hardness and toughness.

This makes it a favored choice for those who need a blade capable of maintaining a sharp edge through extensive use.

440C Steel: Corrosion-resistant but Softer

440C steel is recognized for its good corrosion resistance, which is beneficial in environments where moisture is a factor.

However, it typically does not achieve the same level of hardness as SK-5 steel.

This can result in a knife that doesn’t hold its edge as long, making SK-5 a preferred option for those prioritizing sharpness retention.

AUS-8 Steel: Tough but Prone to Dulling

AUS-8 steel is appreciated for its toughness, allowing it to withstand significant impact without chipping.

However, its relative softness means it can dull more quickly under heavy use.

In comparison, SK-5 steel provides a better balance that addresses both edge retention and durability.

Cost Efficiency of SK-5 Steel

An appealing aspect of SK-5 steel is its cost efficiency. It is often more affordable than both 440C and AUS-8, making it an attractive option for hobbyists and professionals alike who seek quality without a steep price.

This affordability, combined with its performance characteristics, makes SK-5 a popular choice in the knife-making community.

Competitiveness in Application Scenarios

- Competitive in Various Applications: SK-5 steel is used in many areas, especially for outdoor and heavy-duty tools.

- Survival and Camping Knives: It shines in knives for survival and camping, where strength and sharpness are vital. SK-5 stays sharp and strong, even when stressed, without losing performance.

- Kitchen Knives: While stainless steel resists rust better, SK-5 keeps a sharp edge and is a good choice for quality food prep blades.

- Affordability: SK-5 is cost-effective, allowing for a wide range of products. It’s used in everything from high-end custom knives to affordable everyday options.

- Market Presence: Its qualities ensure SK-5’s spot in the competitive world of tools and knife making.

Application of SK-5 in Pocket Knives

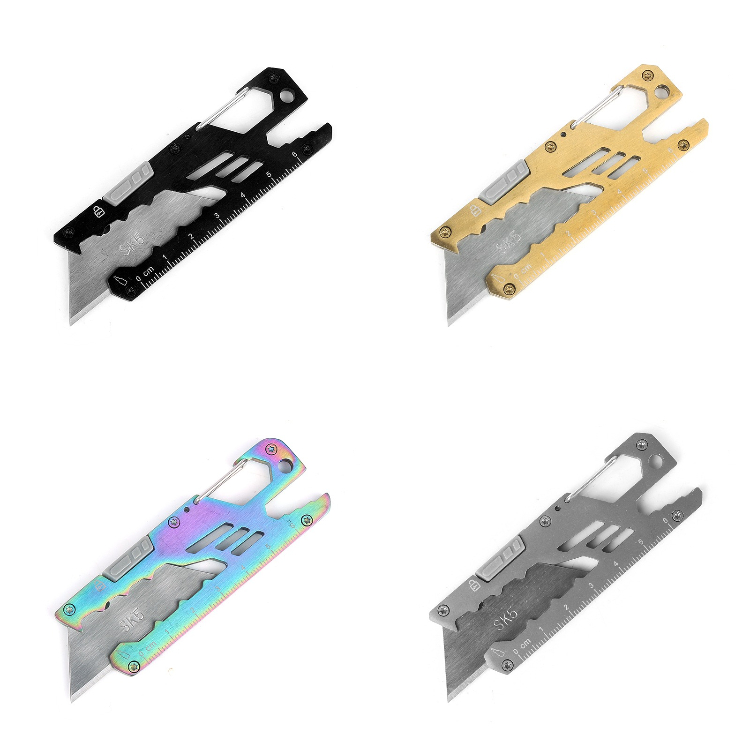

Product Example Analysis

One popular example of SK-5 steel in use is the outdoor pocket knife, which is designed for various tasks while camping or hiking.

These knives are often compact and easy to carry, making them perfect for cutting rope, preparing food, or opening packages.

The strength of SK-5 steel allows these knives to stay sharp and handle tough jobs, which is important for outdoor enthusiasts.

Users appreciate how well the blade performs over time, even during demanding activities.

Another good example is the SK-5 survival knife, which is made for use in emergencies. These knives typically have a thicker blade, providing extra durability when chopping or slicing tough materials.

The combination of toughness and wear resistance makes SK-5 survival knives reliable during outdoor adventures.

Many people choose these knives because they know they can trust them to work hard when needed, ensuring they are ready for any challenge.

Performance Advantages

- Sharpness Retention: SK-5 steel holds its sharp edge for a long time, making it ideal for cutting tasks without the need for frequent sharpening.

- Impact Resistance: This steel can withstand strong hits without chipping, ensuring that your knife remains effective even in tough conditions.

- Ease of Sharpening: Unlike some harder steels, SK-5 can be sharpened relatively easily, allowing users to maintain their blades with minimal effort.

- Versatile Use: SK-5 knives are suitable for a wide range of activities, from camping and hunting to everyday tasks, making them a practical choice for many.

- Reliability in Extreme Conditions: The toughness of SK-5 steel helps it to perform well, even in challenging environments, ensuring that it won’t fail when you need it most.

- Comfort in Handling: Many knives made with SK-5 steel have ergonomic designs, providing comfort during use and reducing hand fatigue.

Limitations and Usage Scenarios

While SK-5 steel has many advantages, it also has some limitations. One significant drawback is its lower corrosion resistance compared to stainless steel.

This means that in very wet or humid conditions, SK-5 knives can rust if not cared for properly.

Although SK-5 holds a sharp edge well, it may need sharpening sooner than harder steels like 440C after heavy use.

Therefore, it is best suited for outdoor activities where the risk of moisture can be managed, such as camping or hiking, rather than for continuous use in wet environments like fishing.

Users should ensure regular maintenance to keep their SK-5 knives in good condition.

Maintenance and Care of SK-5 Steel

To keep your SK-5 steel knives in top condition, follow these cleaning, maintenance, and storage tips:

- Cleaning After Use:

- Wipe the blade with a soft cloth to remove dirt and moisture.

- For tougher spots, use mild soap and warm water, then rinse and dry immediately.

- Regular Maintenance:

- Sharpening: Sharpen the blade regularly using a whetstone or sharpening tool to maintain its edge.

- Oiling: Apply a light coat of mineral oil or knife oil to the blade after cleaning to prevent rust.

- Storage Recommendations:

- Store knives in a dry place, away from humidity.

- Use a knife block, sheaths, or magnetic strips to protect the edge and blade.

Importance of Proper Maintenance

Proper maintenance can significantly extend the service life of your SK-5 knife. By regularly cleaning and oiling your blade, you prevent rust and wear, ensuring it remains sharp and effective for longer periods.

Keeping the knife stored correctly also helps avoid accidental damage, contributing to overall durability.

Following these simple steps ensures you get the best performance from your SK-5 steel knives, making them reliable tools for years to come.

Market and User Perspectives on SK-5

Users generally appreciate SK-5 steel for its good balance of quality and price.

Many enthusiasts and professionals highlight that it performs well for various tasks, especially outdoor activities like camping and hiking.

Customers often note its sharpness retention and ease of sharpening, making it user-friendly and efficient for daily use.

However, some users express concerns about its susceptibility to rust, especially in wet conditions, which highlights the importance of taking care of the knives.

Market Positioning of SK-5 in Knife Manufacturing

In the knife manufacturing market, SK-5 steel has secured a notable position due to its combination of affordability and high performance.

It competes well with other steels like 440C and AUS-8, particularly in the budget-friendly segment, appealing to both hobbyists and seasoned users.

SK-5’s versatility allows manufacturers to create a wide range of knives, from high-end custom models to everyday options.

This adaptability has cemented SK-5’s reputation as a dependable choice for toolmakers who want quality without a hefty price tag, making it a popular steel in various knife markets.

Conclusion

Shieldon offers an extensive OEM service, specialising in the design and manufacturing of high-quality knives, including those made with SK-5 steel.

This service allows clients to customise their knives to fit specific requirements, ensuring that every blade meets the desired functionality and aesthetic appeal.

When considering SK-5 steel for pocket knives, it is crucial to recognize its advantages, such as excellent sharpness retention, impact resistance, and versatility for various uses, particularly in outdoor environments.

However, potential drawbacks like lower corrosion resistance and the need for more frequent sharpening compared to harder steels should not be overlooked.

To make an informed choice, customers should assess their intended use, manage moisture exposure, and establish a maintenance routine to keep the knife in optimal condition.

Prioritizing these factors will help ensure they select an SK-5 steel pocket knife that effectively meets their needs while lasting for years to come.

FAQ

What is the typical hardness range for SK-5 steel?

The typical hardness range for SK-5 steel is between 55 to 60 HRC (Rockwell Hardness Scale). This level of hardness provides a good balance of edge retention and toughness, making it suitable for a variety of cutting tasks while maintaining durability in demanding applications.

How does the performance of SK-5 steel compare to other steels like 440C?

SK-5 steel generally offers good performance in terms of edge retention and toughness, suitable for a wide range of cutting tasks.

Compared to 440C, which is known for its higher corrosion resistance and hardness (typically around 58 to 60 HRC), SK-5 may require more frequent sharpening, especially after heavy use.

While 440C excels in environments where rust is a concern, SK-5 performs better in dry conditions and is easier to sharpen.

Ultimately, the choice between the two steels depends on the intended use; SK-5 is ideal for outdoor activities with manageable moisture, whereas 440C is better suited for applications demanding superior corrosion resistance.

Which well-known pocket knife brands use SK-5 steel in their products?

Many well-known pocket knife brands feature SK-5 steel in their products.

Brands like Ontario Knife Company and Cold Steel are popular choices that make durable knives using SK-5.

Additionally, some models from brands like Morakniv and Ka-Bar also include SK-5 steel, making them trusted options for those looking for quality knives at reasonable prices.

These brands are recognized for creating reliable tools suitable for outdoor activities and everyday use, combining the benefits of SK-5 steel with solid craftsmanship.

Are there any special requirements for the machining and heat treatment processes of SK-5 steel?

Yes, there are some special requirements for the machining and heat treatment of SK-5 steel.

During machining, it’s important to use sharp tools and keep the cutting area cool to avoid damaging the steel.

For heat treatment, SK-5 steel is typically heated to a high temperature and then cooled quickly to harden it.

This process enhances its toughness and edge retention. However, it’s crucial to control the temperature and cooling rate carefully to prevent the steel from becoming too brittle.

Proper handling during these processes ensures that the SK-5 steel performs well in its intended use.

What is the availability of SK-5 steel, and is it easily obtainable?

SK-5 steel is generally available and can be found at many suppliers that sell knife-making materials. It is often used in a variety of knife brands, making it relatively easy to find in finished products like pocket knives.

Whether you’re looking for raw SK-5 steel for forging or a ready-made knife, you should have no trouble locating it through online retailers or local hardware stores that specialize in tools and materials.

This accessibility makes SK-5 a popular choice for both amateur and professional knife makers.