aytem Blg.: YC02

Segment ng item: Natitiklop na kutsilyo draft

Materyal ng talim: Nakabinbin

Panghawakan ang materyal: Nakabinbin

Blade HRC: Nakabinbin

Sukat at timbang: Nakabinbin

Estilo ng talim: Pamantayang punto

Kulay ng hawakan: Nakabinbin

Pocket clip: Tip-up

Mekanismo ng lock: Nakabinbin

Bukas na daan: Flipper

Pagtatapos ng talim: Nakabinbin

Giling ng talim: Nakabinbin

Puna:

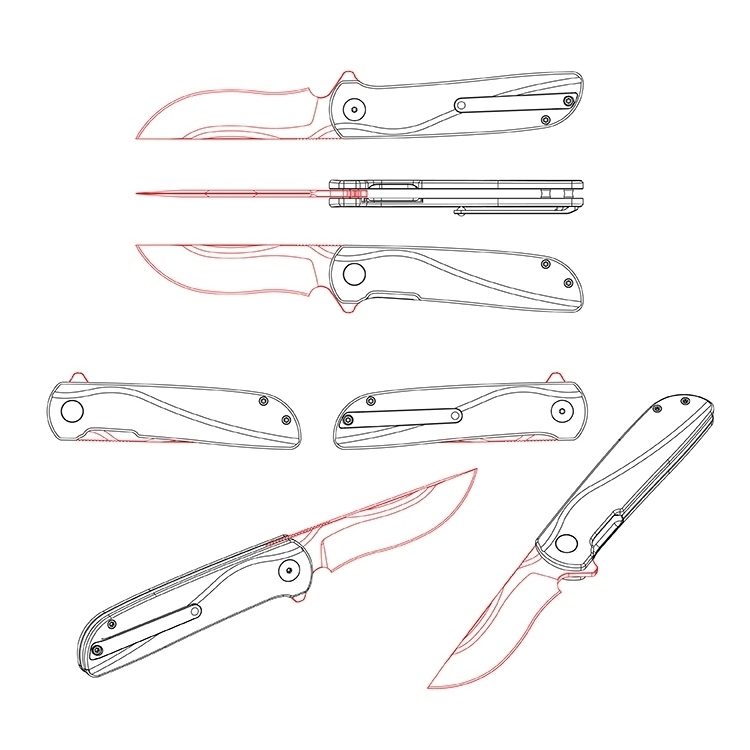

Embarking on a new venture in the world of everyday carry knives, Shieldon presents the YC02 – a folding knife draft that blends classic design with modern utility. The YC02 is conceptualized to be a versatile, reliable companion for those who demand excellence in their EDC gear. With its standard point blade and nested liner lock, this knife draft is the foundation upon which a fully tailored cutting instrument will be crafted, following the final requirements of our clients.

Item NO.: YC02

The YC02 draft is the latest addition to Shieldon’s illustrious collection, promising to deliver a folding knife that resonates with precision, durability, and elegance. It represents a canvas waiting to be painted with the unique desires and specifications of our partners.

Item Segment: Folding Knife Draft

As a draft offering in the folding knife segment, the YC02 is designed with adaptability in mind. This knife awaits the customization that will elevate it to a specialized tool, honed for the discerning user who values both form and function in their everyday carry.

Blade Material: Pending

The heart of the YC02 lies in its blade, and the choice of material is critical to defining its character. Whether the final product will utilize the classic resilience of carbon steel or the advanced performance of modern super steels will depend on the intended use-case scenarios and customer preferences.

Handle Material: Pending

The handle, serving as the interface between hand and blade, is yet to be defined in terms of material. Choices will range from luxurious natural materials like wood and bone, to innovative synthetics and metals, each offering a different look, feel, and level of durability.

Blade HRC: Pending

Hardness, as measured by the Rockwell scale (HRC), is a bespoke feature that will be determined based on the balance between the need for edge retention and ease of maintenance—a softer blade for durability and ease of sharpening, or a harder blade for peak performance in edge retention.

Size and Weight: Pending

The dimensions and heft of the YC02 will be finely tuned to the user’s requirements, ensuring a knife that feels right at home in the pocket and hand. Whether the aim is for a lightweight, unnoticeable carry or a more substantial tool, these specifications will be adjusted accordingly.

Blade Style: Standard Point

With a standard point blade, the YC02 is set to be a quintessential multi-purpose knife. This style is revered for its ability to perform a wide range of cutting tasks, offering an excellent balance between piercing and slicing capabilities.

Handle Color: Pending

The color of the handle remains an open choice, ready to be tailored to the brand’s aesthetic or the functional needs of the knife’s environment. The palette can range from understated tones for tactical use to vibrant colors for personal expression or high visibility.

Pocket Clip: Tip-up

The YC02 will feature a tip-up pocket clip, designed for a convenient and secure carry. This detail ensures that the knife is poised for quick access, enabling swift deployment in any situation.

Lock Mechanism: Pending

A nested liner lock is proposed for its reliable performance and streamlined profile, but the final selection of the lock mechanism will take into account the desired balance of security, ease of use, and manufacturing considerations.

Bukas na Daan: Flipper

The flipper mechanism is chosen for the YC02 to allow for an effortless and ambidextrous one-handed opening. This feature is not only practical but also adds a level of safety, keeping fingers clear of the blade’s path as it snaps into place.

Blade Finish: Pending

The blade finish will be a defining feature of the YC02’s aesthetic and functional attributes. Options could include a satin finish for a classic look, a stonewashed finish for hiding wear, or a DLC coating for ultimate durability and corrosion resistance.

Blade Grind: Pending

The grind of the blade – the factor that greatly influences cutting performance – remains to be specified. From the versatility of a full flat grind to the strength of a saber grind, the end use will dictate the optimal choice.

Konklusyon

The YC02’s potential is as broad as the horizons of our clients’ imaginations. It stands as a testament to Shieldon’s dedication to creating folding knives that not only meet but exceed the expectations of a diverse clientele. This draft is an invitation to embark on a journey of creation, where each pending choice is an opportunity to customize and perfect a knife that aligns with the specific demands and desires of its final wielder.

Shieldon’s commitment to quality and partnership ensures that every step of the YC02’s evolution – from a detailed draft to a high-performance EDC knife – is marked by collaboration, precision, and respect for the client’s vision. As we finalize each specification of the YC02, our clients can trust that the resulting product will be a folding knife of unmatched quality, ready to claim its place in pockets and collections the world over.

When it comes to crafting the ideal folding knife, the marriage of form and function is paramount. This is where Shieldon distinguishes itself in the industry, offering unparalleled OEM/ODM folding knife project services. With a unique understanding that different materials necessitate different minimum order quantities (MOQs), Shieldon prides itself on its unparalleled ability to offer flexible order quantities, ensuring that your maximum budget expectations are met without compromise.

Material Selection and MOQs

At the heart of every quality folding knife lies the choice of materials, which dictates not only the aesthetic and tactile qualities but also the performance and longevity of the final product. Shieldon provides a comprehensive selection of materials, ranging from various grades of stainless steel to high-performance alloys, and from traditional wood to modern composites for handles. Each material carries its own set of characteristics and, correspondingly, its own MOQ requirements.

Understanding these requirements, Shieldon works meticulously to balance the economies of scale with the needs of our customers. For high-end, rare, or custom materials that typically demand higher MOQs due to their cost and special handling, Shieldon employs strategic sourcing and inventory management to offer lower MOQs than traditionally available. This agility affords our clients the flexibility to order premium materials within their budget constraints.

Flexible Quantity Solutions

Shieldon recognizes that every client’s needs are unique, and their orders may range from small, bespoke batches for exclusive designs to larger quantities for widespread distribution. We bridge this gap by providing flexible quantity solutions. Our production setup is optimized for various scales, ensuring that each project—regardless of size—receives the same attention to detail and quality assurance.

This flexibility empowers both emerging businesses looking to enter the market without overcommitting resources and established brands seeking to test new designs before a full-scale launch. Shieldon’s nuanced approach to MOQs allows our clients to scale their orders in alignment with market response and their financial strategies.

Budget Expectation Maximization

Shieldon’s collaborative process begins with an understanding of the client’s budgetary framework. By offering various pricing tiers based on materials and order volumes, we ensure that you can maximize the potential of your investment. Our team of experts is dedicated to advising on cost-effective material choices and design modifications that can optimize your budget without diluting the knife’s quality or design integrity.

We operate on a transparent pricing model that includes consultation on how different materials and order sizes can impact costs. This enables our clients to make informed decisions that best suit their financial requirements and market strategies.

Customization and Design Flexibility

Our OEM/ODM services thrive on customization. With each project, clients can express their brand’s identity through the design and materials of their folding knife. Whether it’s a unique blade profile, a specific handle texture, or a custom color scheme, Shieldon’s flexible manufacturing process accommodates individual customization needs.

Clients can start with a prototype batch, allowing for market testing and feedback incorporation before committing to full-scale production. This iterative approach to design and manufacturing ensures that the final product is not only in line with the vision but also resonates with the end-users.

Quality Across Quantities

Regardless of the order size, Shieldon guarantees consistent quality. Our quality control systems are aligned with international standards, and every knife is subject to rigorous inspection at various stages of production. This commitment ensures that, from a single piece to thousands, each folding knife reflects Shieldon’s reputation for excellence.

Global Sourcing and Supply Chain Excellence

With a global network of material suppliers, Shieldon leverages its sourcing capabilities to provide a vast array of options for every component of the folding knife. Our supply chain expertise ensures not only the availability of diverse materials but also the timely and efficient production of orders.

Partnership and Collaboration

At Shieldon, we see our clients as partners. We believe in open communication, collaboration, and shared success. By working closely with our clients throughout the project—from initial concept to final delivery—we build relationships that extend beyond mere transactions.

After-Sales Support and Continuous Improvement

Our service doesn’t end at delivery. We provide comprehensive after-sales support to address any concerns and to ensure customer satisfaction. We also use feedback to continuously improve our processes and services, aiming to exceed expectations with every new project.

Konklusyon

In the dynamic market of folding knives, Shieldon stands out as a partner that offers not just manufacturing services but a full spectrum of solution-oriented approaches to meet the diverse needs of our clients. We understand the nuances of material MOQs and budget constraints, and we are committed to providing flexible quantity options to accommodate your financial considerations.

With Shieldon, you gain access to a world of possibilities with a range of materials, expert guidance, and a commitment to quality, all structured around your budgetary needs. Whether you’re an independent designer, a startup brand, or an established company looking to expand your product line, Shieldon’s OEM/ODM folding knife project service is your gateway to achieving your vision. We invite you to experience the Shieldon difference, where every project is crafted with precision, passion, and a deep understanding of the intricate dance between affordability and quality.

Handa kaming tumulong sa anumang yugto ng iyong OEM knife project. Ipadala sa amin ang iyong katanungan at ang iyong badyet at babalikan ka namin sa loob 24 na oras.