The Blacksmith Hierophant MS01A Knife is a kakaiba at makabagong produkto, designed and crafted with the utmost attention to detail by Matthew Szymanski and Shieldon.

The design process was comprehensive and incorporated both traditional techniques as well as modern engineering principles.

From the selection of materials to the final testing and polishing, every step in the creation of this knife has been carefully considered.

This painstakingly detailed process ensures that each knife produced is strong, sharp, reliable, and aesthetically pleasing.

With its perfect balance between form and function, it’s no surprise that this beautiful knife has become so popular among professional chefs around the world.

Read more to know how Matt and Shieldon collaborated to make this project successful!

Steps of How Blacksmith Hierophant MS01A Knife Came to Life

Discussion about Draft with Shieldon Team

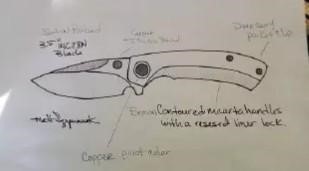

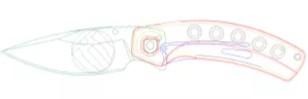

To figure out how to create something really unique, Matthew, a novice designer with little expertise with engineering software but a lifetime enthusiasm for knives, draws out a number of ideas.

Matt had previously pitched his designs to knife manufacturers, but they were all rejected.

He recognizes that he has a long way to go before becoming a well-known designer.

Discussion about the Blade

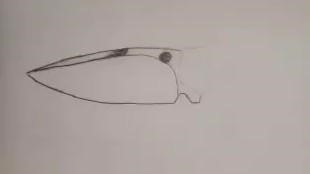

Matt was friendly and willing to engage in conversation with Shieldon at any time. He sees the back spine of the blade take on this shape in his mind.

There was a vast diversity of designs in his sketchbook, suggesting he was knowledgeable of many different styles and developed expertise through study.

Matt saw each sketch as an opportunity to further his artistic knowledge.

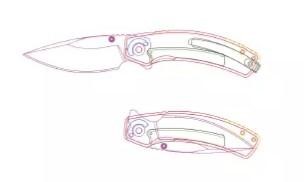

Blade structure creatio

After Shieldon and Matt discussed the blade feature, Shieldon fashioned it to look like the image, winning Matt’s approval.

We had a lengthy team discussion to determine the best course of action. Matt is very detail oriented.

He always aims for the highest standards possible.

Pangasiwaan ang proseso ng paggawa

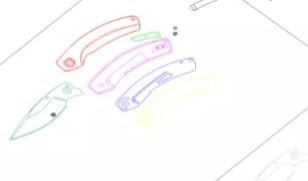

Our experts all agreed that a curved G10 handle would be ideal, which made it much simpler to finish the aesthetic concept.

The pocket clip negotiations were put on hold while the knife’s grip was being finished.

Deep carry process

One of the main points of discussion is the appropriate placement of the deep carry clip in relation to the pommel (the end tip of the handle).

It may be difficult to retrieve an item from a pocket if it were concealed thoroughly.

In the end, we settled on a 95% deep carry clip, with the handle just peeking out of the pocket.

Since two fingers may now fit within the space, holding the handle is much simpler.

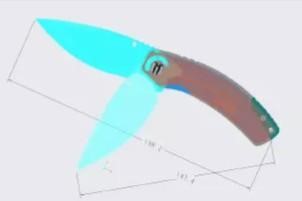

Discussion of the knife dimensions

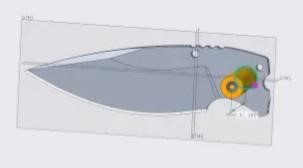

The knife was disassembled after careful inspection of its individual parts in order to get accurate dimensions.

Our experts had to construct an interior framework and make sure everything fit together safely.

This is not a straightforward process in reality. CNC engineering is a demanding field that has tested the mettle of many engineers.

Shieldon required precision to the nearest 0.01mm since our team could not afford to make any errors, even the errors of up to 0.2 mm are allowed during manufacture in the common industry standard.

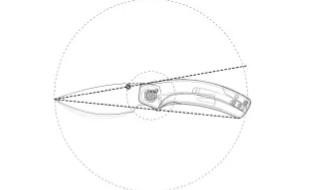

Checking the transparent image to see the inner working of the knife

The knife appears clear as day in the image, allowing us to calculate its blade length of 3.39 inches (86 millimeters) and total size of 7.87 inches (200 millimeters).

All components are visible for precise and accurate determination of this remarkable product’s measurements!

Shape checking

Shieldon defines the visual and ergonomic criteria, as well as the cultural relevance, of a modern EDC blade.

Producing a single unit in this manner is not difficult, but keeping this quality for subsequent products is more challenging to ensure.

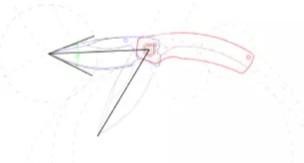

Pivot structuring ng kutsilyo

The hardest part is probably working with the knife’s pivot. The opening action of the knife is affected.

If the blade is not perfectly circular to the inside of the handle, the sharpened edge might be exposed, posing a danger to the user, or the blade could be destroyed if the edge came into contact with the backspacer or went over it.

While making the visuals, our professionals constantly test the pivot to make sure it revolves precisely where it should.

Visualizing a CAD drawing of the blade

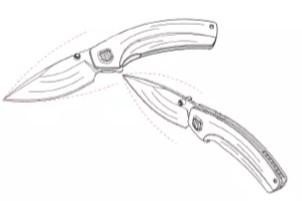

When the knife’s pivot is in position, it’s virtually done.

At long last, a blueprint of the new blade’s engineering has been revealed.

Designer Matt gave it the name “Hierophant” to reflect the mystical religious connotations it inspires.

Isara at buksan ang kutsilyo

The picture clearly shows that the blade fits securely into the handle when the knife is closed.

A large choil is left in place even after a hole has been drilled into the handle, granting users an unshakable grip while they work.

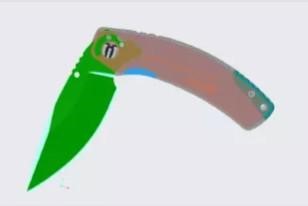

Choice of color

Shieldon’s experts decided to create the image while debating the optimal color of G10 to use in manufacturing.

Matt insisted on using a one-of-a-kind color, and we all agreed that it complemented the Hierophant logo beautifully.

After lengthy deliberation, experts landed on a light color that is close to white.

The Hierophant Knife Name

In religious groups, the job of the hierophant is to guide devotees to sacred places.

It follows that a hierophant is a person who sheds light on mystical beliefs and practices.

As the knife is opened, it takes on the form of a hierophant delivering a message to his followers.

Reorganization of the knife

Before sending the components to the workshop to be processed by the CNC machine, Shieldon always has the graphic engineer reorganize it all and make sure everything fits together.

Because of this, we were able to readjust the thumb stud’s position from the handle.

That’s an essential step before starting mass production.

Final Blacksmith Hierophant product

Honeydew G10 was chosen for the ergonomic grip, while jade G10 was chosen for the back spacer after much deliberation.

In today’s knife market, honeydew, like the ambiance of a cathedral, should be a highly valued color.

Jade G10 glows like a spotlight on every prayer, from the high altar to the church floor.

Buod

With our thorough procedure, you can rest assured that your purchase will be of the highest quality and will also look great, feel great, and be safe to use.

For this reason, Shieldon produces some of the finest everyday carry (EDC) blades available. We appreciate you taking the time to learn more about the Hierophant and our development process.

We hope this article has given you a deeper appreciation for the work that goes into creating a high-quality everyday carry blade. Contact Shieldon and get more information about EDC fashion.

Shieldon、Facebook、Instagram、YouTube、Twitter、Tumblr、Pinterest